Effects of other ships and berths - Chemical tanker procedure

Tugs and other craft alongside chemical tankers

The number of craft which come alongside and the duration of their stay should be kept to a minimum. Subject also to port authority regulations, only authorised craft having the permission of the responsible officer, and where applicable the terminal representative, should be permitted to come alongside or remain alongside a chemical tanker while it is engaged in cargo operations.

If an unauthorised craft comes alongside or operates in an area which may create a danger, it should be reported to the port authority and, if necessary, cargo transfer operations should cease.

The number of craft which come alongside and the duration of their stay should be kept to a minimum. Subject also to port authority regulations, only authorised craft having the permission of the responsible officer, and where applicable the terminal representative, should be permitted to come alongside or remain alongside a chemical tanker while it is engaged in cargo operations.

If an unauthorised craft comes alongside or operates in an area which may create a danger, it should be reported to the port authority and, if necessary, cargo transfer operations should cease.

The responsible officer should instruct personnel manning any craft alongside that the same safety regulations that apply on

the chemical tanker must be observed on the craft. In the event of a breach of the regulations operations should be stopped,

and should not be restarted until the situation has been made safe.

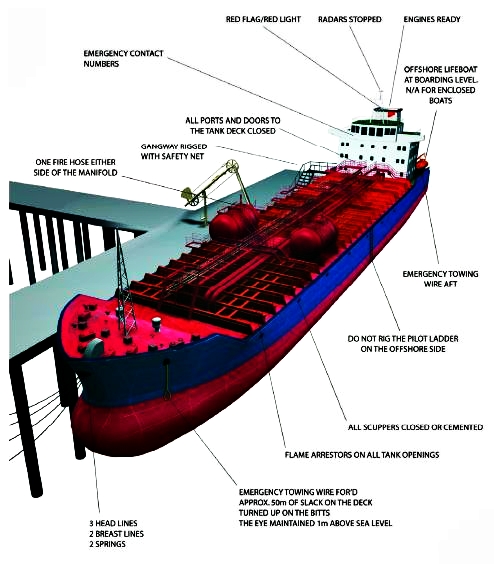

Fig:Chemical tanker general safety precautions at berth

Other tankers at adjacent berths

Even when no cargo operations are being undertaken while at a terminal, dangerous concentrations of cargo vapour may be encountered if cargo or ballast handling, inerting, tank cleaning or gas freeing operations are being conducted by another tanker at an adjacent berth. In such circumstances appropriate precautions should be taken.

Chemical tanker operations at general cargo berths

Where chemical tanker operations need to be conducted at general cargo berths it is unlikely that personnel on such berths will be familiar with the full range of safety requirements relating to possible sources of ignition, or that cranes or other equipment will comply with the requirements for the design and installation of electrical equipment in hazardous areas.

The master may therefore have to insist on precautions additional to those set out in this chapter. Such precautions could include restricted vehicular access, removable barriers, additional fire fighting equipment and control of sources of ignition, together with restrictions on the movement of goods and operation of cargo handling equipment.

Local national or port regulations may require additional notices, and such requirements should be observed.

SBM

Whilst lying at a SBM mooring it is imperative that the vessel does not ride up on the buoy. The position of the buoy in relation to the vessels bow must be monitored continuously. The crewmembers assigned for this duty shall be fully instructed / familiarised regarding their duties and reporting requirements. Many terminals use a pull off tug on the stern to maintain constant tension in the mooring. The tow line shall be monitored for condition / protected from chafing throughout the operation.

Anchors shall be kept secured by lashings throughout with the stopper in place. Some SBM terminals may require the bridge to be continuously manned by an officer whilst moored.

CBM / MBM

Due to the nature of the mooring employed an emergency departure for the berth is complex. The operating limits will take into account the additional time required to vacate the berth in deteriorating conditions. Tandem Operations Many of the requirements for SBM operations apply also for tandem mooring operations.

Tankers intending to conduct tandem operations should be provided with the OCIMF publication - Tandem Mooring and Offloading Guidelines for Conventional Tankers at F(P)SO Facilities.

Related info:

Emergency towing off wires and access to ship requirements

Mooring precautions for chemical tankers at berth

Assessing wind & weather conditions

Restriction on using radio equipments and other mobile devices in cargo working areas

Main Info pages!

Home page ||| Chemical hazards ||| Cargo planning & Stowage ||| Cargo loading ||| Cargo documents ||| Safe stability ||| Cargo care ||| Preparation for unloading ||| Inert gas systems |||Gas freeing ||| Nitrogen handling ||| Chemical handling Safe practice |||Handling equipments ||| Cargo & Ballast pumps ||| Cargo tanks |||Tank cleaning |||Special cargoes |||Spills emergencies |||Fire protection

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.

Fig:Chemical tanker general safety precautions at berth

Other tankers at adjacent berths

Even when no cargo operations are being undertaken while at a terminal, dangerous concentrations of cargo vapour may be encountered if cargo or ballast handling, inerting, tank cleaning or gas freeing operations are being conducted by another tanker at an adjacent berth. In such circumstances appropriate precautions should be taken.

Chemical tanker operations at general cargo berths

Where chemical tanker operations need to be conducted at general cargo berths it is unlikely that personnel on such berths will be familiar with the full range of safety requirements relating to possible sources of ignition, or that cranes or other equipment will comply with the requirements for the design and installation of electrical equipment in hazardous areas.

The master may therefore have to insist on precautions additional to those set out in this chapter. Such precautions could include restricted vehicular access, removable barriers, additional fire fighting equipment and control of sources of ignition, together with restrictions on the movement of goods and operation of cargo handling equipment.

Local national or port regulations may require additional notices, and such requirements should be observed.

SBM

Whilst lying at a SBM mooring it is imperative that the vessel does not ride up on the buoy. The position of the buoy in relation to the vessels bow must be monitored continuously. The crewmembers assigned for this duty shall be fully instructed / familiarised regarding their duties and reporting requirements. Many terminals use a pull off tug on the stern to maintain constant tension in the mooring. The tow line shall be monitored for condition / protected from chafing throughout the operation.

Anchors shall be kept secured by lashings throughout with the stopper in place. Some SBM terminals may require the bridge to be continuously manned by an officer whilst moored.

CBM / MBM

Due to the nature of the mooring employed an emergency departure for the berth is complex. The operating limits will take into account the additional time required to vacate the berth in deteriorating conditions. Tandem Operations Many of the requirements for SBM operations apply also for tandem mooring operations.

Tankers intending to conduct tandem operations should be provided with the OCIMF publication - Tandem Mooring and Offloading Guidelines for Conventional Tankers at F(P)SO Facilities.

Related info:

Emergency towing off wires and access to ship requirements

Mooring precautions for chemical tankers at berth

Assessing wind & weather conditions

Restriction on using radio equipments and other mobile devices in cargo working areas

Main Info pages!

Home page ||| Chemical hazards ||| Cargo planning & Stowage ||| Cargo loading ||| Cargo documents ||| Safe stability ||| Cargo care ||| Preparation for unloading ||| Inert gas systems |||Gas freeing ||| Nitrogen handling ||| Chemical handling Safe practice |||Handling equipments ||| Cargo & Ballast pumps ||| Cargo tanks |||Tank cleaning |||Special cargoes |||Spills emergencies |||Fire protection

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.