Safe method of gas freeing after a tank cleaning onboard chemical tankers

Gas freeing onboard chemical tankers is required for entry into cargo tanks, for hot works or washing for clean ballast tanks. Gas Freeing is one of the most hazardous operations routinely undertaken onboard a Chemical Tanker and the additional risk created by cargo gases expelled from the tanks, which may be toxic, flammable and corrosive, cannot be over-emphasised.

It is therefore extremely important that all care is exercised during gas freeing operations as the consequences of an inadvertent error can be serious and have far reaching consequences for personnel and the environment.

A space is considered as “gas free” when the concentration of flammable gases in its atmosphere is less than 0% LEL, the concentration of toxic gases (including IG components) is less than the TLV and the Oxygen concentration is not less than 20.8%.

Hazards may encounter at various stages. The following recommendations apply to cargo tank gas freeing in general. The IBC Code contains advice about cargo tank gas freeing .

It is essential to know what type of vapours can be expected: they may be flammable and/or toxic and/or corrosive:

a) Venting of toxic and flammable gas during gas freeing should be through the vessel's approved gas freeing outlets, and therefore the exit velocity should be sufficient to carry the vapours clear of the deck. No escape of cargo vapours should occur at deck level before the concentration within the tank has fallen below 30% LFL and the relevant TLV. Thereafter, final clearance of the vapour mixture may continue at tank deck level through other larger deck openings.

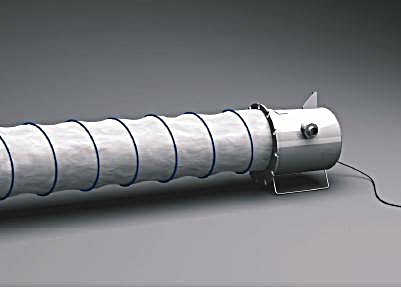

Fig:Chemical tanker tank ventilation hose

b) If portable ventilation equipment is to be used to blow air into a tank, tank openings should be kept closed until work on that tank is about to commence.

c) Where cargo tanks are gas freed by means of permanently installed fans, air is introduced into the cargo tank through the cargo lines. The entire line system should be thoroughly drained before venting to avoid any obstruction of the air flow or tendency for water or cargo residues to be blown into a cargo tank. Valves on the systems, other than those required for ventilation, should be closed and secured. The fans should normally be blanked or disconnected from the cargo tank system when not in use.

d) Fixed gas freeing equipment should not be used for gas freeing of a tank while simultaneously being used to ventilate another tank in which washing is in progress, regardless of the capacity of the equipment.

e) Portable fans should only be used if they are water driven, or hydraulically or pneumatically driven. Their construction materials should be such that no hazard of incendiary sparking arises if, for any reason, the impeller touches the inside of the casing. The manufacturer's recommendations for maintenance should be followed. Guards should be in place to prevent accidental contact with fan blades.

f) Portable fans, where used, should be placed in such positions and the ventilation openings so arranged that all parts of the tank being ventilated are effectively and equally gas freed. Fans should generally be as remote as possible from the ventilation outlets.

g) Portable fans should be so connected to the deck that an effective electrical bond exists between the fan and the deck.

h) The wind direction may cause cargo vapours to pass near to air intakes for accommodation spaces or engine room ventilation, and necessitate additional precautions . Central air conditioning or mechanical ventilation system intakes should be adjusted to prevent the entry of gas, if possible by using recirculation of air within the spaces.

i) If at any time it is suspected that gas is being drawn into the accommodation block, the central air conditioning and any mechanical ventilating systems should be stopped and the intakes covered or closed. It is unlikely that any ship now uses window-type air conditioning units which draw in air from outside the superstructure, but any which are still in use, or other plants which are not certified as safe for use in the presence of flammable gas, should be electrically disconnected and any external vents or intakes closed.

j) If the tanks are connected by a common venting system, each tank should be isolated to prevent the transfer of gas to or from other tanks.

k) When a tank appears to have been gas freed and all mechanical ventilation has been stopped, a period of about ten minutes should elapse before taking final gas measurements. This allows relatively stable conditions to develop within the tank space. Tests should then be made at several levels and, where the tank is sub-divided by a wash bulkhead, in each compartment of the tank. In large compartments such tests should be made at widely separate positions. If satisfactory gas readings are not obtained, the tank should be checked for cargo residues and then ventilation resumed.

l) On completion of all gas freeing and tank washing, the gas venting system should be carefully checked, particular attention being paid to the efficient working of the P/V valves and any high velocity vent valves. If the valves or vent risers are fitted with devices designed to prevent the passage of flame, these should also be checked, and cleaned if found necessary. Gas vent risers and their drains should be checked to ensure that they are free of any blockage.

m) On completion of gas freeing, attention should be given to all equipment that has been used, and to enclosed or partially enclosed spaces that can retain or contain cargo residues or vapours, so that no unsuspected dangerous pockets can remain. Places where such cargo traces may exist include cargo lines, cargo valves, cargo pumps, stripping lines and valves, venting lines and P/V valves, vapour return lines, ullaging or sounding arrangements, heating coils, cargo handling equipment store rooms, protective clothing store rooms and cargo sample store rooms.

Related Info:

Gas freeing safety precautions for chemical tankers

A space is considered as “gas free” when the concentration of flammable gases in its atmosphere is less than 0% LEL, the concentration of toxic gases (including IG components) is less than the TLV and the Oxygen concentration is not less than 20.8%. Comply with IBC/BCH code and ICS Chemical Tanker safety Guide requirement for gas freeing for chemical cargoes. (Ref IBC code CH.8) .....

Supply of Nitrogen from shore - safety guideline

It is a frequent practice at chemical loading ports to control the atmosphere in cargo tanks with nitrogen supplied from shore, for the purpose of drying a tank and its associated piping system, purging a tank before loading the cargo or padding cargo in a tank. ....

How to test a tank environment prior entry ?

Entry into an enclosed space that is not in normal daily use, great care should be taken to create and maintain safe working conditions, even if the duration of the work is to be short. Many fatalities in enclosed spaces have resulted from entering such spaces without proper supervision or adherence to agreed procedures. In almost every case the fatality would have been avoided if the simple guidance in this section had been followed. ....

Personal safety for working in cargo tanks and other enclosed spaces

On chemical tankers entry of personnel into cargo tanks is a more common practice than it is on oil tankers. Chemical tanker operators' instructions often make special allowance for this when describing procedures for entry into cargo tanks. The intention is to avoid causing a comparatively routine event to distract everyone's attention, but equally to ensure that adequate checks are conscientiously made and recorded....

<Pump room hazards safety precautions

On tankers equipped with a cargo pump-room, this is a potentially hazardous enclosed space. Pump alarms and trips, level alarms etc. should be tested regularly, and in any case before commencing cargo handling operations, to ensure that they are functioning correctly. The results of such tests should be recorded. .....

Dräger Toxic Gas Detector Extension Hoses Correction Factor

Chemical detector tubes: These instruments, often referred to as Draeger tubes, normally function by drawing a sample of the atmosphere to be tested through a proprietary chemical reagent in a glass tube. The detecting reagent becomes progressively discoloured if a contaminant vapour is present in the sample.....

Poisoning and required first aid treatment onboard

The poison is a very toxic substance which when absorbed into the human body by ingestion, skin absorption, or inhalation produces a serious or fatal effect. Poison may enter the human body orally, by inhalation, or by skin contact. After being absorbed by the body it may affect certain organs or give a general poisonous effect. Lately the cancerogene effects of some industrial chemicals have been noticed. This has led to significant reductions of hereto accepted TLV- values in many countries....

Reference Publications :

Main Info pages!

Home page ||| Chemical hazards ||| Cargo planning & Stowage ||| Cargo loading ||| Cargo documents ||| Safe stability ||| Cargo care ||| Preparation for unloading ||| Inert gas systems |||Gas freeing ||| Nitrogen handling ||| Chemical handling Safe practice |||Handling equipments ||| Cargo & Ballast pumps ||| Cargo tanks |||Tank cleaning |||Special cargoes |||Spills emergencies |||Fire protection

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.

Gas freeing onboard chemical tankers is required for entry into cargo tanks, for hot works or washing for clean ballast tanks. Gas Freeing is one of the most hazardous operations routinely undertaken onboard a Chemical Tanker and the additional risk created by cargo gases expelled from the tanks, which may be toxic, flammable and corrosive, cannot be over-emphasised.

It is therefore extremely important that all care is exercised during gas freeing operations as the consequences of an inadvertent error can be serious and have far reaching consequences for personnel and the environment.

A space is considered as “gas free” when the concentration of flammable gases in its atmosphere is less than 0% LEL, the concentration of toxic gases (including IG components) is less than the TLV and the Oxygen concentration is not less than 20.8%.

Hazards may encounter at various stages. The following recommendations apply to cargo tank gas freeing in general. The IBC Code contains advice about cargo tank gas freeing .

It is essential to know what type of vapours can be expected: they may be flammable and/or toxic and/or corrosive:

a) Venting of toxic and flammable gas during gas freeing should be through the vessel's approved gas freeing outlets, and therefore the exit velocity should be sufficient to carry the vapours clear of the deck. No escape of cargo vapours should occur at deck level before the concentration within the tank has fallen below 30% LFL and the relevant TLV. Thereafter, final clearance of the vapour mixture may continue at tank deck level through other larger deck openings.

Fig:Chemical tanker tank ventilation hose

b) If portable ventilation equipment is to be used to blow air into a tank, tank openings should be kept closed until work on that tank is about to commence.

c) Where cargo tanks are gas freed by means of permanently installed fans, air is introduced into the cargo tank through the cargo lines. The entire line system should be thoroughly drained before venting to avoid any obstruction of the air flow or tendency for water or cargo residues to be blown into a cargo tank. Valves on the systems, other than those required for ventilation, should be closed and secured. The fans should normally be blanked or disconnected from the cargo tank system when not in use.

d) Fixed gas freeing equipment should not be used for gas freeing of a tank while simultaneously being used to ventilate another tank in which washing is in progress, regardless of the capacity of the equipment.

e) Portable fans should only be used if they are water driven, or hydraulically or pneumatically driven. Their construction materials should be such that no hazard of incendiary sparking arises if, for any reason, the impeller touches the inside of the casing. The manufacturer's recommendations for maintenance should be followed. Guards should be in place to prevent accidental contact with fan blades.

f) Portable fans, where used, should be placed in such positions and the ventilation openings so arranged that all parts of the tank being ventilated are effectively and equally gas freed. Fans should generally be as remote as possible from the ventilation outlets.

g) Portable fans should be so connected to the deck that an effective electrical bond exists between the fan and the deck.

h) The wind direction may cause cargo vapours to pass near to air intakes for accommodation spaces or engine room ventilation, and necessitate additional precautions . Central air conditioning or mechanical ventilation system intakes should be adjusted to prevent the entry of gas, if possible by using recirculation of air within the spaces.

i) If at any time it is suspected that gas is being drawn into the accommodation block, the central air conditioning and any mechanical ventilating systems should be stopped and the intakes covered or closed. It is unlikely that any ship now uses window-type air conditioning units which draw in air from outside the superstructure, but any which are still in use, or other plants which are not certified as safe for use in the presence of flammable gas, should be electrically disconnected and any external vents or intakes closed.

j) If the tanks are connected by a common venting system, each tank should be isolated to prevent the transfer of gas to or from other tanks.

k) When a tank appears to have been gas freed and all mechanical ventilation has been stopped, a period of about ten minutes should elapse before taking final gas measurements. This allows relatively stable conditions to develop within the tank space. Tests should then be made at several levels and, where the tank is sub-divided by a wash bulkhead, in each compartment of the tank. In large compartments such tests should be made at widely separate positions. If satisfactory gas readings are not obtained, the tank should be checked for cargo residues and then ventilation resumed.

l) On completion of all gas freeing and tank washing, the gas venting system should be carefully checked, particular attention being paid to the efficient working of the P/V valves and any high velocity vent valves. If the valves or vent risers are fitted with devices designed to prevent the passage of flame, these should also be checked, and cleaned if found necessary. Gas vent risers and their drains should be checked to ensure that they are free of any blockage.

m) On completion of gas freeing, attention should be given to all equipment that has been used, and to enclosed or partially enclosed spaces that can retain or contain cargo residues or vapours, so that no unsuspected dangerous pockets can remain. Places where such cargo traces may exist include cargo lines, cargo valves, cargo pumps, stripping lines and valves, venting lines and P/V valves, vapour return lines, ullaging or sounding arrangements, heating coils, cargo handling equipment store rooms, protective clothing store rooms and cargo sample store rooms.

Related Info:

Gas freeing safety precautions for chemical tankers

A space is considered as “gas free” when the concentration of flammable gases in its atmosphere is less than 0% LEL, the concentration of toxic gases (including IG components) is less than the TLV and the Oxygen concentration is not less than 20.8%. Comply with IBC/BCH code and ICS Chemical Tanker safety Guide requirement for gas freeing for chemical cargoes. (Ref IBC code CH.8) .....

Supply of Nitrogen from shore - safety guideline

It is a frequent practice at chemical loading ports to control the atmosphere in cargo tanks with nitrogen supplied from shore, for the purpose of drying a tank and its associated piping system, purging a tank before loading the cargo or padding cargo in a tank. ....

How to test a tank environment prior entry ?

Entry into an enclosed space that is not in normal daily use, great care should be taken to create and maintain safe working conditions, even if the duration of the work is to be short. Many fatalities in enclosed spaces have resulted from entering such spaces without proper supervision or adherence to agreed procedures. In almost every case the fatality would have been avoided if the simple guidance in this section had been followed. ....

Personal safety for working in cargo tanks and other enclosed spaces

On chemical tankers entry of personnel into cargo tanks is a more common practice than it is on oil tankers. Chemical tanker operators' instructions often make special allowance for this when describing procedures for entry into cargo tanks. The intention is to avoid causing a comparatively routine event to distract everyone's attention, but equally to ensure that adequate checks are conscientiously made and recorded....

<Pump room hazards safety precautions

On tankers equipped with a cargo pump-room, this is a potentially hazardous enclosed space. Pump alarms and trips, level alarms etc. should be tested regularly, and in any case before commencing cargo handling operations, to ensure that they are functioning correctly. The results of such tests should be recorded. .....

Dräger Toxic Gas Detector Extension Hoses Correction Factor

Chemical detector tubes: These instruments, often referred to as Draeger tubes, normally function by drawing a sample of the atmosphere to be tested through a proprietary chemical reagent in a glass tube. The detecting reagent becomes progressively discoloured if a contaminant vapour is present in the sample.....

Poisoning and required first aid treatment onboard

The poison is a very toxic substance which when absorbed into the human body by ingestion, skin absorption, or inhalation produces a serious or fatal effect. Poison may enter the human body orally, by inhalation, or by skin contact. After being absorbed by the body it may affect certain organs or give a general poisonous effect. Lately the cancerogene effects of some industrial chemicals have been noticed. This has led to significant reductions of hereto accepted TLV- values in many countries....

Reference Publications :

- IBC/BCH Code

- IMO – Inert Gas Systems

- Ship’s “Inert Gas Systems Instruction Manual” (Approved by Class)

- Ship’s “Procedure and Arrangements Manual” (Approved by Class)

- International Safety Guide for Oil Tankers and Terminals (ISGOTT)

- ICS Chemical Tanker safety Guide

- SOLAS

Main Info pages!

Home page ||| Chemical hazards ||| Cargo planning & Stowage ||| Cargo loading ||| Cargo documents ||| Safe stability ||| Cargo care ||| Preparation for unloading ||| Inert gas systems |||Gas freeing ||| Nitrogen handling ||| Chemical handling Safe practice |||Handling equipments ||| Cargo & Ballast pumps ||| Cargo tanks |||Tank cleaning |||Special cargoes |||Spills emergencies |||Fire protection

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.