Cargo tank & enclosed space entry procedure for chemical tankers

On chemical tankers the entry of personnel into cargo tanks is a more common practice than

on oil tankers as a result of the requirement for inspections between grades etc; despite this,

it is essential that the necessary checks are conscientiously made and recorded prior to entry

in order to ensure the safety of personnel, enclosed space rescue equipment must be made

ready for immediate use.

On Chemical Tankers, entry into enclosed spaces should be treated with the same extreme caution .Entry into Enclosed Spaces, must be adhered to. The SCAFFTAG Enclosed Space Tag system must be in place to indicate which cargo tanks are safe for entry; these should be placed at the tank accesses or hatches. In the absence of a suitable “Safe Condition” tag, entry is prohibited.

On Chemical Tankers, entry into enclosed spaces should be treated with the same extreme caution .Entry into Enclosed Spaces, must be adhered to. The SCAFFTAG Enclosed Space Tag system must be in place to indicate which cargo tanks are safe for entry; these should be placed at the tank accesses or hatches. In the absence of a suitable “Safe Condition” tag, entry is prohibited.

Fig: Wearing breathing apparatus

Tank fans : Tank fans are most commonly used for ventilating cargo tanks.They are normally supplied with flexible ducting that may be lowered or pushed into the tank. The further that the ducting can be placed into the tank ( without its operator entering into the tank ) , the more effective it is.

Each member of the team entering the enclosed space must utilise the “Man in Tank” tags by clipping them onto the Entry Tag.

Entry into non gas free space / contaminated cargo tanks is prohibited, unless a risk assessment has been carried out and approved by the management office responsible for the vessel.

If this is agreed to, then in such cases, spaces should only be entered by personnel wearing breathing apparatus and appropriate protection against exposure to flammable, toxic or corrosive cargo vapours and, if practicable, a lifeline. Prior to such entry, reference must be made to ISGOTT, Chapter 11, Section 11.4.4,, ICS Chemical Tanker Safety Guide, Chapter 3.5 and IBC code concerning entry with Breathing Apparatus.

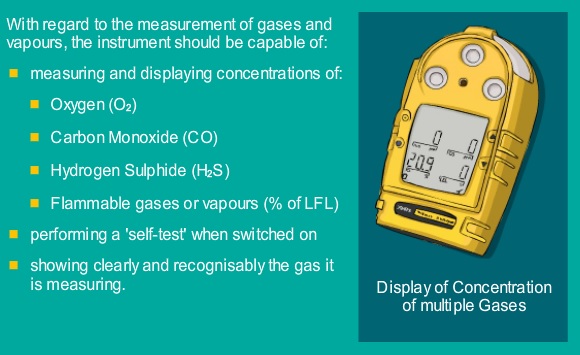

Fig: Multi gas detector

Fig: Tank fan

- A permit must be issued by the Master stating that there is no practicable alternative to the proposed method of entry.

- Ventilation is provided where possible, provided this does not create a flammable atmosphere,

- Personnel use PPE and positive pressure breathing apparatus and are connected, where practicable, to a lifeline

- Means of communication are provided and a system of signals is agreed and understood by the personnel involved.

- Spare sets of breathing apparatus, a resuscitator and rescue equipment are available outside the space and a standby party with breathing apparatus donned is in attendance in case of an emergency.

- Work carried out in such circumstances will be limited to absolutely essential maintenance and or inspection only.

Cargoes such as of Coconut Oil may give off dangerous concentrations of CO (Carbon Monoxide) and when entry into tanks is required for “squeezing,” readings for CO in ppm (in addition to LEL, 02, H2S) must be checked and monitored prior to and during entry of personnel. Tank must be gas free 0% LEL, less than TLV for CO, H2S etc and personal gas meters with alarms should be used by persons entering the space.

If personnel are required to enter cargo tanks for hand cleaning with all Enclosed Space Entry precautions and procedures must be observed prior to and during entry, in such cases, full protective clothing and self-contained breathing apparatus must be worn.

Related Info:

How to determine the level of a liquid in a chemical tank

Poisoning and required first aid treatment onboard

After tank cleaning gas freeing safety guideline for chemical tankers

Checklist for handling dangerous liquid chemicals in bulk

Preparations prior allowing personnel into cargo tanks / enclosed spaces

How to rescue injured or unconscious person from enclosed spaces

Preparations for hot work and safety precautions

Pre-cleaning /washing of cargo tanks

Final cleaning of cargo tanks prior loading

Tank cleaning and posoning hazards

Testing of tanks and cargoes

Practical tank cleaning methods for various noxious liquid cargo

Special tank cleaning method

Determining proper tank cleaning by acid wash method

Supervision of all tank cleaning and gas freeing operations

Disposal of tank washings, slops and dirty ballast - safe method

Main Info pages!

Home page ||| Chemical hazards ||| Cargo planning & Stowage ||| Cargo loading ||| Cargo documents ||| Safe stability ||| Cargo care ||| Preparation for unloading ||| Inert gas systems |||Gas freeing ||| Nitrogen handling ||| Chemical handling Safe practice |||Handling equipments ||| Cargo & Ballast pumps ||| Cargo tanks |||Tank cleaning |||Special cargoes |||Spills emergencies |||Fire protection

Reference publications

- Equipment Manufacturers Instruction Manuals

- MARPOL – 73/78 (latest consolidated edition)

- International Safety Guide for Oil Tankers and Terminals (ISGOTT)

- CFR 33 parts 125 to 199

- Ship to Ship Transfer Guide (Petroleum)

- MSDS for particular cargo carried

- Chemical Tank Cleaning Guide

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.