Intact stability guideline for double hull chemical tankers

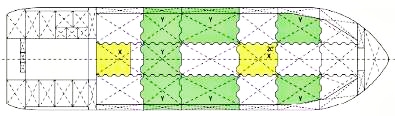

Normally chemical tankers have large number of tanks and this is not an issue. Some older

Type III vessels may have this type of configuration. It is important that the stability aspects of

these type of double hull vessels is understood as there have been a number of serious incidents

involving loss of stability.

In contrast to conventional tankers which are inherently stable, it is recognised that double hull structures which do not have a centre line bulkhead have potential problems in that large free surface effects may be encountered at various stages of cargo and ballast operations. As a consequence, a loss of GM may result in serious stability problems.

In contrast to conventional tankers which are inherently stable, it is recognised that double hull structures which do not have a centre line bulkhead have potential problems in that large free surface effects may be encountered at various stages of cargo and ballast operations. As a consequence, a loss of GM may result in serious stability problems.

It must be stressed that

Masters and Officers must be fully aware of this potential problem, and that all cargo and ballast

operations are conducted strictly in accordance with the vessel’s approved loading manual.

Changes to cargo plans must be fully assessed before the revised plan is undertaken.

All ships are supplied with stability data, and loading and unloading instructions to comply with

statutory requirements. These instructions are to be carefully studied and followed. Generally,

these instructions will specify a maximum number of tanks, which may be slack at any one time.

Sometimes it may be necessary to adjust the quantity of cargo to be loaded in order to avoid slack tanks. Where double bottom ballast tanks extend across the whole width of the vessel, the free surface effect of water in these tanks will be as great as that of full width cargo tanks and account must be taken of this fact.

The Cargo Loading/Discharging plan must also take into account the problems of free surface and any limitations on the number of tanks which may be slack at any one time.

In order to ensure adequate monitoring of the vessel’s stress and stability condition, calculations must be made and recorded, using the vessel loading computer, on an hourly basis during cargo and ballast operations.

If a loss of stability becomes evident during loading or discharging, all cargo, ballast and bunker operations must be stopped and a plan prepared to restore positive stability. If the vessel is at a terminal this plan must be agreed with the terminal representative and the cargo hoses are to be disconnected.

In all cases the Master shall positively verify the number of allowed slack tanks and post a clear notice of instruction according in the cargo control room.

Slack tanks and sloshing effects

It is essential that Masters and Officers be aware that the partial loading of a cargo tank with cargo ballast may present a potential problem. The combination of free surface and the flat bottom can result in the generation of wave energy of sufficient power to severely damage internal structures and pipelines and heating coils.

The movement of liquid within a cargo tank when the vessel is rolling or pitching in a seaway is also called “sloshing”. In general the negative effects of sloshing can be summarised as follows:

Required documents:

Related Info:

Intact stability guideline for double hull chemical tankers

Cargo calculation -safety factors

Handling of high vapour pressure cargoes, topping off procedure & use of compressed gas during chemical cargo loading

Loading / stress computer for chemical tankers

Main Info pages!

Home page ||| Chemical hazards ||| Cargo planning & Stowage ||| Cargo loading ||| Cargo documents ||| Safe stability ||| Cargo care ||| Preparation for unloading ||| Inert gas systems |||Gas freeing ||| Nitrogen handling ||| Chemical handling Safe practice |||Handling equipments ||| Cargo & Ballast pumps ||| Cargo tanks |||Tank cleaning |||Special cargoes |||Spills emergencies |||Fire protection

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.

Sometimes it may be necessary to adjust the quantity of cargo to be loaded in order to avoid slack tanks. Where double bottom ballast tanks extend across the whole width of the vessel, the free surface effect of water in these tanks will be as great as that of full width cargo tanks and account must be taken of this fact.

The Cargo Loading/Discharging plan must also take into account the problems of free surface and any limitations on the number of tanks which may be slack at any one time.

In order to ensure adequate monitoring of the vessel’s stress and stability condition, calculations must be made and recorded, using the vessel loading computer, on an hourly basis during cargo and ballast operations.

If a loss of stability becomes evident during loading or discharging, all cargo, ballast and bunker operations must be stopped and a plan prepared to restore positive stability. If the vessel is at a terminal this plan must be agreed with the terminal representative and the cargo hoses are to be disconnected.

In all cases the Master shall positively verify the number of allowed slack tanks and post a clear notice of instruction according in the cargo control room.

Slack tanks and sloshing effects

It is essential that Masters and Officers be aware that the partial loading of a cargo tank with cargo ballast may present a potential problem. The combination of free surface and the flat bottom can result in the generation of wave energy of sufficient power to severely damage internal structures and pipelines and heating coils.

The movement of liquid within a cargo tank when the vessel is rolling or pitching in a seaway is also called “sloshing”. In general the negative effects of sloshing can be summarised as follows:

- The slamming effect of the liquid inside the tank may result in serious damages to the tank structure and fittings.

- Even a slight rolling and pitching motion can generate the main source of ignition – an electrostatic charge. An electrically charged mist can also occur in the tank partially filled with a mixture of oil and water, such as dirty ballast, tank washings or slops. During tank cleaning continuously monitor the tank being washed to ensure water is not building up in the tank and sloshing in heavy weather.

- The effect of free surface reduces the ship’s GM and may even lead to a loss of stability. In order to eliminate these problems, slack tanks must be avoided wherever possible, and it is imperative that no cargo tank, unless so designed and permitted by Classification, is allowed to remain in a slack condition whilst the vessel is at sea. The Ship’s Trim and Stability manual approved by Classification and/or the Appendix to the Classification Certificate must be referred to on this matter.

Required documents:

- Ship’s “Trim and Stability Data/Manual” (Approved by Class)

- Ship’s “Procedures and Arrangements Manual” (Approved by Class)

- Ship’s Damaged Stability Manual

Related Info:

Intact stability guideline for double hull chemical tankers

Cargo calculation -safety factors

Handling of high vapour pressure cargoes, topping off procedure & use of compressed gas during chemical cargo loading

Loading / stress computer for chemical tankers

Main Info pages!

Home page ||| Chemical hazards ||| Cargo planning & Stowage ||| Cargo loading ||| Cargo documents ||| Safe stability ||| Cargo care ||| Preparation for unloading ||| Inert gas systems |||Gas freeing ||| Nitrogen handling ||| Chemical handling Safe practice |||Handling equipments ||| Cargo & Ballast pumps ||| Cargo tanks |||Tank cleaning |||Special cargoes |||Spills emergencies |||Fire protection

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.