Pre-loading meeting, ship & terminal agreements for chemical cargo loading

The complexity of loading/discharging operations on chemical tankers makes it

necessary to plan all activities in which vessel and terminal are involved.

Parties involved are from terminal a loading Master, from ship Master/Chief officer & an expert surveyor.

The surveyor is present as an independent expert commissioned by the shipper, charterer

and plays an important role in tank inspection, cargo quantity loaded and cargo analysis. The

agreements between the parties are put in writing.

Vessel – Terminal agreements

The Master/Chief officer should present the Notice of Readiness (NOR) to the loading master for his signature. The loading master is the addressee for all protests in connection with loading. The Chief- Officer and loading master will discuss the loading programme.

All relevant items in the Ship / Shore Safety Checklist, as provided by the terminal, are to be completed by the Terminal Representative and the Chief Officer. If no safety checklist is provided by the terminal, or it is not to the same standard as that contained within ISGOTT, the ISGOTT (5th Edition) Ship/Shore Safety Checklist, including Part C Bulk Liquid Chemicals, must be used. Agreements specific to the ship and the cargo are to be made. Depending on the particular situation this may include:

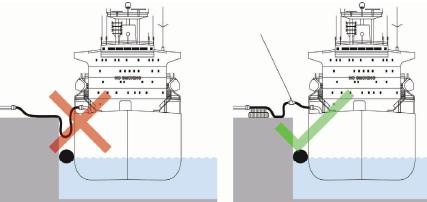

Fig:Cargo hose support between ship & quay

Preparation before cargo loading

Before cargo loading starts, the responsible officer should be satisfied that all relevant precautions been observed . Pre cargo loading meeting shall be carried out between ship and Terminal .

The following important pre-loading checks are to be made by the ship:

Local and terminal regulations have been received in writing and are being observed Agreement has been reached with the responsible terminal representative about:

Cargo-hoses, loading arms and gaskets are suitable and certified for the intended cargo and are in good condition. Flexible hoses should be suspended by suitable straps and not subjected to excessive bending or put excessive strain on the cargo manifold. Mechanical loading arms must be supported in a way that they do not put excessive force on the manifold.

Care should be taken to protect manifolds from mechanical damage. The ship’s own cargo hoses should not normally be used for shore connection and in case they are used, they must be tested and certified as per regulation in the IBC code and LOI received. Also check they are compatible with products to load and are clean

Before commencing loading the responsible officer must ensure that the cargo lines are set in the correct loading mode, and that cargo venting system is set as per regulation, i.e. open Or controlled venting as per IBC code.

Certain cargoes require vapour return to the shore facility. The responsible officer must ensure that the shore and ship vapour system are compatible and that the system is operated in compliance with these procedures, local and terminal regulations. VECS Manual to be complied with.

Related Info:

Preparations for cargo operations

Closed loading requirement of various grade liquid chemicals and related considerations

Voyage planning and related considerations

Cargo sampling safety precautions

Preparation for cargo operation

Preparing a cargo tank atmosphere

Cargo unloading operation safety precautions

Liaison between ship and shore

Cargo care during transit

Ship shore safety checklist while alongside a terminal

Preparation for chemical cargo loading

Handling of high vapour pressure cargoes, topping off procedure & use of compressed gas during chemical cargo loading

How to prepare a cargo loading or discharge program ?

How to avoid solidification in cargo tanks ?

Cargo line clearance requirement for chemical tankers

Cargo segregation requirement for chemical tankers

How to arrange disposal of tank cleaning waste ?

Restrictions on discharge cargo residue into sea

Retention of slops on chemical tankers

Vapour emission control requirement for chemical tankers

Handling self reactive chemicals

Handling of toxic chemical cargoes

Main Info pages!

Home page ||| Chemical hazards ||| Cargo planning & Stowage ||| Cargo loading ||| Cargo documents ||| Safe stability ||| Cargo care ||| Preparation for unloading ||| Inert gas systems |||Gas freeing ||| Nitrogen handling ||| Chemical handling Safe practice |||Handling equipments ||| Cargo & Ballast pumps ||| Cargo tanks |||Tank cleaning |||Special cargoes |||Spills emergencies |||Fire protection

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.

The Master/Chief officer should present the Notice of Readiness (NOR) to the loading master for his signature. The loading master is the addressee for all protests in connection with loading. The Chief- Officer and loading master will discuss the loading programme.

All relevant items in the Ship / Shore Safety Checklist, as provided by the terminal, are to be completed by the Terminal Representative and the Chief Officer. If no safety checklist is provided by the terminal, or it is not to the same standard as that contained within ISGOTT, the ISGOTT (5th Edition) Ship/Shore Safety Checklist, including Part C Bulk Liquid Chemicals, must be used. Agreements specific to the ship and the cargo are to be made. Depending on the particular situation this may include:

- Shipping document for cargo to be loaded

- Inhibitor or stabilization certificate as per IBC code

- End of loading- Ship stop/shore stop

- Loading rate (m3/h)

- Closed loading procedure

- Quantity to be loaded including options

- Topping off procedure

- Cargo data: Grades of cargo to be loaded and manifold connections, sequence & specific weight, ‘in air’ or ‘in vacuum’ correction factors, loading temperature, Hazardous chemical data sheet for manufacturer

- Blowing of the loading lines as necessary

- Use of the vapour return if required

- Purging if required

- Blanketing with nitrogen if required

- Port and terminal regulations, nautical warnings and information

- In case several parcels are loaded through the same line, binding order and sequence of loading.

- Manifold samples

- Heating instructions from the shipper

- Inhibitor certificate (for monomer cargoes).

Fig:Cargo hose support between ship & quay

Preparation before cargo loading

Before cargo loading starts, the responsible officer should be satisfied that all relevant precautions been observed . Pre cargo loading meeting shall be carried out between ship and Terminal .

The following important pre-loading checks are to be made by the ship:

- Product characteristics must be known, including compatibility with other cargoes, heat sensitivity, risk of exothermic self-reaction, toxicity and general safe handling practices.

- Normally tanks to be loaded are pre-inspected for cleanliness by independent surveyors. The responsible officer should satisfy himself that the tanks to be inspected are well ventilated and safe to enter . The surveyor must be accompanied by the responsible officer or a person delegated by him.

- Tanks passed for loading should be tightly secured with all cargo openings closed, except when tanks are to be nitrogen purged

- MSDS, PPE, Antidote and appropriate gas detector tubes availability.

- Tank instrumentation (level gauges, level alarms, thermometers etc) must be tested for operation and accuracy.

- Remote valve closing devices, cargo pump/line pressure gauges must be checked and tested.

- All cargo tank P.V valves are to be checked or operability and that vent lines are ensured, drained and clear.

- Pressure gauges are to be fitted to the offshore manifold for the purpose of checking any leakage during loading operations

- Cargo lines and crossovers to be inspected and all drain plugs closed and secured.

- Cargo manifolds should be ready for shore hose connection with only the connecting side end blank removed and tagged with tank name and product to be loaded. All unused flange connections are to be blanked and fully bolted.

- Fire protection equipment must be inspected and ready for immediate use.

- Protective clothing and breathing apparatus are being worn or are immediately available as necessary.

Local and terminal regulations have been received in writing and are being observed Agreement has been reached with the responsible terminal representative about:

- signals to indicate “stand by”, “start operation”, “slow down”, “stop operations “

- pumping rates

- pumping and loading sequence

- action to be taken in case of fire or other emergency

- emergency shutdown procedures.

- access to the ship, and smoking restrictions

- sampling procedure, could include manifold, pump stack and foot samples and will they be running or require stops.

- Will lines be purged with N2 prior to loading?

- a ship-shore bonding connection, if used, is made before hoses are connected, and if an insulating flange is used, its insulation has not been impaired.

Cargo-hoses, loading arms and gaskets are suitable and certified for the intended cargo and are in good condition. Flexible hoses should be suspended by suitable straps and not subjected to excessive bending or put excessive strain on the cargo manifold. Mechanical loading arms must be supported in a way that they do not put excessive force on the manifold.

Care should be taken to protect manifolds from mechanical damage. The ship’s own cargo hoses should not normally be used for shore connection and in case they are used, they must be tested and certified as per regulation in the IBC code and LOI received. Also check they are compatible with products to load and are clean

Before commencing loading the responsible officer must ensure that the cargo lines are set in the correct loading mode, and that cargo venting system is set as per regulation, i.e. open Or controlled venting as per IBC code.

Certain cargoes require vapour return to the shore facility. The responsible officer must ensure that the shore and ship vapour system are compatible and that the system is operated in compliance with these procedures, local and terminal regulations. VECS Manual to be complied with.

Related Info:

Preparations for cargo operations

Closed loading requirement of various grade liquid chemicals and related considerations

Voyage planning and related considerations

Cargo sampling safety precautions

Preparation for cargo operation

Preparing a cargo tank atmosphere

Cargo unloading operation safety precautions

Liaison between ship and shore

Cargo care during transit

Ship shore safety checklist while alongside a terminal

Preparation for chemical cargo loading

Handling of high vapour pressure cargoes, topping off procedure & use of compressed gas during chemical cargo loading

How to prepare a cargo loading or discharge program ?

How to avoid solidification in cargo tanks ?

Cargo line clearance requirement for chemical tankers

Cargo segregation requirement for chemical tankers

How to arrange disposal of tank cleaning waste ?

Restrictions on discharge cargo residue into sea

Retention of slops on chemical tankers

Vapour emission control requirement for chemical tankers

Handling self reactive chemicals

Handling of toxic chemical cargoes

Main Info pages!

Home page ||| Chemical hazards ||| Cargo planning & Stowage ||| Cargo loading ||| Cargo documents ||| Safe stability ||| Cargo care ||| Preparation for unloading ||| Inert gas systems |||Gas freeing ||| Nitrogen handling ||| Chemical handling Safe practice |||Handling equipments ||| Cargo & Ballast pumps ||| Cargo tanks |||Tank cleaning |||Special cargoes |||Spills emergencies |||Fire protection

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.