Cargo unloading safety procedure for chemical tankers

Just prior to commencing discharge the responsible officer should check that the cargo pipeline system is set correctly, that

correct valves are open, that valves not being used are closed, and that the cargo venting system is appropriate for the cargo

operation. Particular attention should be paid to ship's cargo discharge equipment, such as pumps and pumproom ventilation

When a vapour balance is to be used by returning inert gas displaced from the shore receiving tank to the ship, the pressure in the ship's cargo tank must be carefully monitored, and necessary action taken to avoid excessive over or underpressure. At the start of any unloading, and at regular intervals throughout the operation, checks should be made to ensure that cargo is not leaking.

When a vapour balance is to be used by returning inert gas displaced from the shore receiving tank to the ship, the pressure in the ship's cargo tank must be carefully monitored, and necessary action taken to avoid excessive over or underpressure. At the start of any unloading, and at regular intervals throughout the operation, checks should be made to ensure that cargo is not leaking.

Adding nitrogen to maintain overpressure

When unloading cargoes that have to be carried under a blanket of nitrogen, it may be necessary to ensure that no air is drawn into the tank. Therefore an overpressure of nitrogen should be maintained as the liquid level falls. The nitrogen can be supplied from stored compressed gas or from a nitrogen generator on board, and be introduced into the tank ullage space. But if it is necessary to obtain nitrogen from the shore, it is essential that the pre-transfer discussion includes agreement on the nitrogen flow rate and pressure to be used.

Although the overpressure required is no more than about 0.2 bar, it is usual for the shore nitrogen supply system to be well above this figure, perhaps as high as 7 bar. Particularly in the early stages when the ullage space is still small, it is possible for the flow rate to exceed the tank venting capacity, and for an overpressure to develop. A safe procedure is to use a pressure reducing device on the nitrogen supply line, and to have a calibrated gauge showing the pressure in the pipeline. There should be direct communication with the terminal, and the ship should monitor cargo tank ullage space pressure throughout.

Sweeping of cargo residues

After the carriage of animal and vegetable oils and fats, manual sweeping of the cargo tanks is usually necessary to push the semi-liquid residues towards the pump suction to complete the discharge, and before commencing tank cleaning. (The process is sometimes called ,squeegeeing' or 'puddling'.) Despite the natural origins of the cargo, it is essential that safety precautions are observed on every occasion that personnel are sent into an enclosed space.

The tank should be mechanically ventilated for at least 1 hour, concurrently with discharge, to ensure its atmosphere is safe for entry without breathing apparatus before sweeping begins. An enclosed space entry permit issued before personnel enter the tank. Ventilation should continue during the sweeping operation. A responsible person should remain in attendance at the tank entry hatch throughout the sweeping operation, keeping the personnel within under observation.

If at any time the oxygen level falls below 21%, the tank must be vacated until the oxygen level has been restored by ventilation.

Completion of discharge

It is essential to reduce the cargo residue in a tank to the minimum attainable. Tanks should be stripped according to the requirements of the ship's P&A Manual.

When discharge of a product is completed, the relevant manifold valve on the ship and the shore should be closed. This will provide separation of the ship and the shore system from a failure or unexpected action in the other. All openings on cargo tanks used for that product must be finally closed and secured.

After completion of discharge, lines and hoses should be cleared to shore. Cargo hoses or arms must only be disconnected from the manifold after they have been drained of cargo residues, and relieved of any pressure.

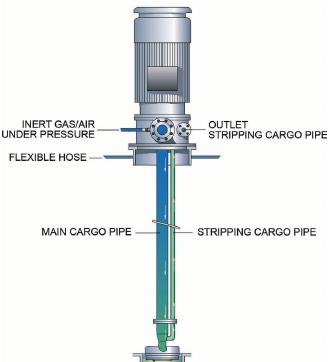

Fig: stripping pump

Cargo tank stripping

The final stage in bulk liquid pumping from a tank or pipeline. To achieve this, it is often necessary to list the ship to avoid suction loss. A large stern trim assists in draining, particularly if product is trapped in the centreline bulkhead corrugations.

Chemical cargoes, which create threat to the marine environment, must be discharged until there is virtually no residue left on board. Modern chemical tankers are designed from the outset with efficient stripping in mind; cargo tanks are smooth-walled, bulkheads are either corrugated or provided with stiffening located in the adjacent spaces. The clearance between the impeller of a submerged pump and the bottom of suction well can be as small as 20 mm. The cargo left in each pump and its piping can be stripped to shore by blowing air or nitrogen through the system. In this arrangement, residue quantities in the region of 50 litres per tank are achievable.

Good practice

As per MARPOL definition (Annex II – Reg.1, ) high viscosity cargo, such as discharging a parcel of Rapeseed Oil, a Pre-wash is required if this cargo is discharged at a viscosity equal to or greater than 50 mPa/s

Related Info:

How to prepare a cargo loading / discharge plan ?

Technical readiness prior loading operations

Voyage planning and related considerations

Cargo sampling safety precautions

Cargo calculation

Signing a bill of lading and related guideline

Preparation for cargo operation

Preparing a cargo tank atmosphere

Cargo unloading operation safety precautions

Liaison between ship and shore

How to prevent cargo pipeline leakage

Ship shore safety checklist while alongside a terminal

Reference publications

Other Info:

Voyage planning and related considerations

Preparation for cargo operation

Preparing a cargo tank atmosphere

Cargo unloading operation safety precautions

Liaison between ship and shore

Cargo line leakage countermeasures

Checklist for handling dangerous liquid chemicals in bulk

Recommended temperature monitoring equipments onboard

Practical example of solving tank cleaning problems

Pre-cleaning /washing of cargo tanks

Risk & hazards of chemical contamination onboard

Cargo compatibility and reactivity of various chemical cargo

Poisoning and required first aid treatment onboard

Chemical tanker safe mooring practice

Determining presence of contaminants in chemical cargo

How to avoid solidification in cargo tanks ?

Cargo segregation requirement for chemical tankers

How to arrange disposal of tank cleaning waste ?

Restrictions on discharge cargo residue into sea

Retention of slops on chemical tankers

Vapour emission control requirement for chemical tankers

Handling self reactive chemicals

Handling of toxic chemical cargoes

Pre-loading meeting safety consideration

How to determine chemical cargo temperatures at different level ?

How to take cargo samples ?

How to avoid solidification in cargo tanks ?

Cargo line clearance requirement for chemical tankers

How to arrange disposal of tank cleaning waste ?

Care of cargo pums - risk of pump overload or underload

Main Info pages!

Home page ||| Chemical hazards ||| Cargo planning & Stowage ||| Cargo loading ||| Cargo documents ||| Safe stability ||| Cargo care ||| Preparation for unloading ||| Inert gas systems |||Gas freeing ||| Nitrogen handling ||| Chemical handling Safe practice |||Handling equipments ||| Cargo & Ballast pumps ||| Cargo tanks |||Tank cleaning |||Special cargoes |||Spills emergencies |||Fire protection

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.

When unloading cargoes that have to be carried under a blanket of nitrogen, it may be necessary to ensure that no air is drawn into the tank. Therefore an overpressure of nitrogen should be maintained as the liquid level falls. The nitrogen can be supplied from stored compressed gas or from a nitrogen generator on board, and be introduced into the tank ullage space. But if it is necessary to obtain nitrogen from the shore, it is essential that the pre-transfer discussion includes agreement on the nitrogen flow rate and pressure to be used.

Although the overpressure required is no more than about 0.2 bar, it is usual for the shore nitrogen supply system to be well above this figure, perhaps as high as 7 bar. Particularly in the early stages when the ullage space is still small, it is possible for the flow rate to exceed the tank venting capacity, and for an overpressure to develop. A safe procedure is to use a pressure reducing device on the nitrogen supply line, and to have a calibrated gauge showing the pressure in the pipeline. There should be direct communication with the terminal, and the ship should monitor cargo tank ullage space pressure throughout.

Sweeping of cargo residues

After the carriage of animal and vegetable oils and fats, manual sweeping of the cargo tanks is usually necessary to push the semi-liquid residues towards the pump suction to complete the discharge, and before commencing tank cleaning. (The process is sometimes called ,squeegeeing' or 'puddling'.) Despite the natural origins of the cargo, it is essential that safety precautions are observed on every occasion that personnel are sent into an enclosed space.

The tank should be mechanically ventilated for at least 1 hour, concurrently with discharge, to ensure its atmosphere is safe for entry without breathing apparatus before sweeping begins. An enclosed space entry permit issued before personnel enter the tank. Ventilation should continue during the sweeping operation. A responsible person should remain in attendance at the tank entry hatch throughout the sweeping operation, keeping the personnel within under observation.

If at any time the oxygen level falls below 21%, the tank must be vacated until the oxygen level has been restored by ventilation.

Completion of discharge

It is essential to reduce the cargo residue in a tank to the minimum attainable. Tanks should be stripped according to the requirements of the ship's P&A Manual.

When discharge of a product is completed, the relevant manifold valve on the ship and the shore should be closed. This will provide separation of the ship and the shore system from a failure or unexpected action in the other. All openings on cargo tanks used for that product must be finally closed and secured.

After completion of discharge, lines and hoses should be cleared to shore. Cargo hoses or arms must only be disconnected from the manifold after they have been drained of cargo residues, and relieved of any pressure.

Fig: stripping pump

Cargo tank stripping

The final stage in bulk liquid pumping from a tank or pipeline. To achieve this, it is often necessary to list the ship to avoid suction loss. A large stern trim assists in draining, particularly if product is trapped in the centreline bulkhead corrugations.

Chemical cargoes, which create threat to the marine environment, must be discharged until there is virtually no residue left on board. Modern chemical tankers are designed from the outset with efficient stripping in mind; cargo tanks are smooth-walled, bulkheads are either corrugated or provided with stiffening located in the adjacent spaces. The clearance between the impeller of a submerged pump and the bottom of suction well can be as small as 20 mm. The cargo left in each pump and its piping can be stripped to shore by blowing air or nitrogen through the system. In this arrangement, residue quantities in the region of 50 litres per tank are achievable.

Good practice

As per MARPOL definition (Annex II – Reg.1, ) high viscosity cargo, such as discharging a parcel of Rapeseed Oil, a Pre-wash is required if this cargo is discharged at a viscosity equal to or greater than 50 mPa/s

Related Info:

How to prepare a cargo loading / discharge plan ?

Technical readiness prior loading operations

Voyage planning and related considerations

Cargo sampling safety precautions

Cargo calculation

Signing a bill of lading and related guideline

Preparation for cargo operation

Preparing a cargo tank atmosphere

Cargo unloading operation safety precautions

Liaison between ship and shore

How to prevent cargo pipeline leakage

Ship shore safety checklist while alongside a terminal

Reference publications

- IBC Code / BCH code

- International Safety Guide for Oil Tankers and Terminals (ISGOTT)

- ICS Chemical Tanker Safety Guide

- Ship’s “Procedure and Arrangements Manual” (Approved by Class)

- Certificate of Fitness for the Carriage of Dangerous Chemicals in Bulk

- Ship’s “VEC System Operational Manual” (Approved by Class)

- Ship to Ship Transfer Guide (Petroleum)

- Tank Cleaning Manual

Other Info:

Voyage planning and related considerations

Preparation for cargo operation

Preparing a cargo tank atmosphere

Cargo unloading operation safety precautions

Liaison between ship and shore

Cargo line leakage countermeasures

Checklist for handling dangerous liquid chemicals in bulk

Recommended temperature monitoring equipments onboard

Practical example of solving tank cleaning problems

Pre-cleaning /washing of cargo tanks

Risk & hazards of chemical contamination onboard

Cargo compatibility and reactivity of various chemical cargo

Poisoning and required first aid treatment onboard

Chemical tanker safe mooring practice

Determining presence of contaminants in chemical cargo

How to avoid solidification in cargo tanks ?

Cargo segregation requirement for chemical tankers

How to arrange disposal of tank cleaning waste ?

Restrictions on discharge cargo residue into sea

Retention of slops on chemical tankers

Vapour emission control requirement for chemical tankers

Handling self reactive chemicals

Handling of toxic chemical cargoes

Pre-loading meeting safety consideration

How to determine chemical cargo temperatures at different level ?

How to take cargo samples ?

How to avoid solidification in cargo tanks ?

Cargo line clearance requirement for chemical tankers

How to arrange disposal of tank cleaning waste ?

Care of cargo pums - risk of pump overload or underload

Main Info pages!

Home page ||| Chemical hazards ||| Cargo planning & Stowage ||| Cargo loading ||| Cargo documents ||| Safe stability ||| Cargo care ||| Preparation for unloading ||| Inert gas systems |||Gas freeing ||| Nitrogen handling ||| Chemical handling Safe practice |||Handling equipments ||| Cargo & Ballast pumps ||| Cargo tanks |||Tank cleaning |||Special cargoes |||Spills emergencies |||Fire protection

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.