Safety precautions for discharging various liquid chemical cargo in bulk

There are large variations in the design of cargo containment and cargo handling systems of modern chemical tankers, and specific ship require special precautions for discharging various grade noxious liquid substances in bulk. Particular attention should be paid to ship’s cargo discharge equipment, such as

pump, pump room ventilation etc. The following precautions should be observed:

A pre-discharge conference with responsible terminal personnel which should include

Prior commencing discharge the responsible officer must ensure that the entire discharge system, including pumps and vents, are secured and ready.

After completion of discharge, including stripping and line clearing to shore (never allow shore to drain lines and hoses back into a ship tank) and hoses are disconnected. Personnel engaged in hose disconnection must wear proper personal protective equipment. All tank openings to be closed and secured.

Discharging agreements

Prior to discharge the ship / shore checklist has to be completed by the chief officer and the loading master. Thereafter they have to agree on the discharge plan. This discharge plan must be completed in writing and approved by the Master.

As a minimum the discharge plan must at least contain the following information:

a) Commencement and execution of the discharge

Before commencement of discharge the following to be carried out:

After confirmation from shore the discharge rate can be increased up to the agreed maximum or maximum backpressure.

When several tanks containing the same cargo are connected i.e. by jumper hoses the risk of causing an overflow due to wrong setting of the valves is increased. In this case the level of the other connected tanks should be continuously monitored. Level alarms must be switched on.

The officer on duty must be available throughout the cargo operation. One watchman is to be on deck in the vicinity of the manifold throughout the entire operation in order that any potential risk is identified immediately and the required steps are taken to promptly control or remedy the risks, such as but not limited to informing the officer on duty etc.

The discharge must be conducted in accordance with the agreement made between the Chief Officer and the Loading master as well as additional instructions / standing orders given by the Chief Officer.

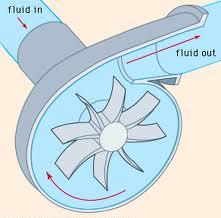

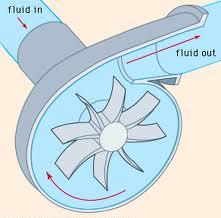

Fig: Chemical tanker cargo pumping

Pumproom precautions – Cargo and Ballast Pump rooms

During the discharge the following, must be checked and complied with:-

Related Info:

Ship shore safety checklist while alongside a terminal

How to prepare a cargo loading / discharge plan ?

Checklist for handling dangerous liquid chemicals in bulk

Adding nitrogen to maintain overpressure & sweeping of cargo residues for animal and vegetable oils upon completion of discharge

What is closed unloading operation ?

Preparing a cargo tank atmosphere

Cargo loading operation detail procedures

Voyage planning and related considerations

Cargo unloading operation safety precautions

Liaison between ship and shore

Preparation for cargo operation

Ship shore safety checklist while alongside a terminal

Ship shore safety checklist while alongside a terminal

How to prepare a cargo loading / discharge plan ?

Handling self reactive chemicals

Handling of toxic chemical cargoes

Cargo handling safe practice for chemical products

Ship & terminal pre-loading meeting prior loading /discharging

Cargo compatibility and reactivity of various chemical cargo

Poisoning and required first aid treatment onboard

Determining presence of contaminants in chemical cargo

Main Info pages!

Home page ||| Chemical hazards ||| Cargo planning & Stowage ||| Cargo loading ||| Cargo documents ||| Safe stability ||| Cargo care ||| Preparation for unloading ||| Inert gas systems |||Gas freeing ||| Nitrogen handling ||| Chemical handling Safe practice |||Handling equipments ||| Cargo & Ballast pumps ||| Cargo tanks |||Tank cleaning |||Special cargoes |||Spills emergencies |||Fire protection

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.

- Characteristics of cargoes to be discharged

- Sequence of cargoes to be discharge

- Temperature of cargoes to be discharged

- Quantities of cargoes to be discharged

- Pumping rates and pressure

- Emergency shutdown procedure

- Mode of communications

- Careful monitoring of discharge temperature to ensure cargoes are not damaged due to over heating or lack of heat and to comply with MARPOL Annex II requirements for category Y high viscosity and solidifying cargoes.

Prior commencing discharge the responsible officer must ensure that the entire discharge system, including pumps and vents, are secured and ready.

After completion of discharge, including stripping and line clearing to shore (never allow shore to drain lines and hoses back into a ship tank) and hoses are disconnected. Personnel engaged in hose disconnection must wear proper personal protective equipment. All tank openings to be closed and secured.

Discharging agreements

Prior to discharge the ship / shore checklist has to be completed by the chief officer and the loading master. Thereafter they have to agree on the discharge plan. This discharge plan must be completed in writing and approved by the Master.

As a minimum the discharge plan must at least contain the following information:

- Manifold connection to be used for each cargo

- Which tanks are to be discharged

- Maximum discharge rate and/or back-pressure

- Discharge sequence and procedure for changing grades

a) Commencement and execution of the discharge

Before commencement of discharge the following to be carried out:

- Cargo pump emergency stop trips are to be tested.

- The Chief Officer is once again to personally check that the correct line up of valves has been made and that all required isolations by spools or spectacles are made.

After confirmation from shore the discharge rate can be increased up to the agreed maximum or maximum backpressure.

When several tanks containing the same cargo are connected i.e. by jumper hoses the risk of causing an overflow due to wrong setting of the valves is increased. In this case the level of the other connected tanks should be continuously monitored. Level alarms must be switched on.

The officer on duty must be available throughout the cargo operation. One watchman is to be on deck in the vicinity of the manifold throughout the entire operation in order that any potential risk is identified immediately and the required steps are taken to promptly control or remedy the risks, such as but not limited to informing the officer on duty etc.

The discharge must be conducted in accordance with the agreement made between the Chief Officer and the Loading master as well as additional instructions / standing orders given by the Chief Officer.

Fig: Chemical tanker cargo pumping

Pumproom precautions – Cargo and Ballast Pump rooms

During the discharge the following, must be checked and complied with:-

- Pumproom ventilation to be in operation throughout the cargo and tank cleaning operations.

- The pumproom(s) is to be checked for leaks at least hourly during the discharge. In order to limit and minimise personal exposure to possible toxic hazards, personnel entering pumprooms for these routine hourly inspections are to be rotated. Personnel entering pumprooms are to make use of personal gas monitoring equipment provided on board.

- The pumproom(s) is to be monitored for hydrocarbons and other possible toxic hazards.

Related Info:

Ship shore safety checklist while alongside a terminal

How to prepare a cargo loading / discharge plan ?

Checklist for handling dangerous liquid chemicals in bulk

Adding nitrogen to maintain overpressure & sweeping of cargo residues for animal and vegetable oils upon completion of discharge

What is closed unloading operation ?

Preparing a cargo tank atmosphere

Cargo loading operation detail procedures

Voyage planning and related considerations

Cargo unloading operation safety precautions

Liaison between ship and shore

Preparation for cargo operation

Ship shore safety checklist while alongside a terminal

Ship shore safety checklist while alongside a terminal

How to prepare a cargo loading / discharge plan ?

Handling self reactive chemicals

Handling of toxic chemical cargoes

Cargo handling safe practice for chemical products

Ship & terminal pre-loading meeting prior loading /discharging

Cargo compatibility and reactivity of various chemical cargo

Poisoning and required first aid treatment onboard

Determining presence of contaminants in chemical cargo

Main Info pages!

Home page ||| Chemical hazards ||| Cargo planning & Stowage ||| Cargo loading ||| Cargo documents ||| Safe stability ||| Cargo care ||| Preparation for unloading ||| Inert gas systems |||Gas freeing ||| Nitrogen handling ||| Chemical handling Safe practice |||Handling equipments ||| Cargo & Ballast pumps ||| Cargo tanks |||Tank cleaning |||Special cargoes |||Spills emergencies |||Fire protection

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.