Heating, high viscosity and solidifying cat X, Y chemical substances- Chemical Tanker Solutions

In a modern chemical tanker in order to maintain product quality, to minimise the potential for discoloration, and to facilitate some liquid cargo transport in a safe manner cargo heating is required. Claims can arise when liquid chemicals not carried at the

recommended temperature. The handling of cargo during

transit is the responsibility of the vessel crew and owner.

This article looks at some issues that the ship crew needs to consider for safe carriage of chemical cargo.

It is sometimes imperative to apply heat during transit to maintain or raise the the temperature of the load. Over or under heating of cargo can negatively affect the property of the shipment and, on many circumstances, this change in the cargo quality is irreversible. Improper temperature control can lead to degeneration in the cargo quality or poor pumping performance leading to excess cargo remaining on board (ROB).

It is sometimes imperative to apply heat during transit to maintain or raise the the temperature of the load. Over or under heating of cargo can negatively affect the property of the shipment and, on many circumstances, this change in the cargo quality is irreversible. Improper temperature control can lead to degeneration in the cargo quality or poor pumping performance leading to excess cargo remaining on board (ROB).

The voyage orders will contain heating information, if heating is required. As a rule the final heating

instructions are given by the Shipper in writing to the Master / Chief Officer in the port of loading.

If those written instructions are not given, the master should request them and issue a Letter of

Protest if they are not received at departure. In the latter case the management office should be

immediately informed.

The heating instructions may contain any, or all, of the following:

Unintended heating

The risk of heating a cargo, which should not be heated, must be eliminated. An ‘unintended heating’ of a cargo can not only influence the quality of the cargo, but can endanger the crew, the vessel and the environment, e.g. lifetime of an inhibitor can be shortened drastically by unintended heating and a monomeric cargo such as styrene monomer can polymerise.

In order to prevent unintended heating of cargoes that do not require heating the following preventive measures should be taken:

Heating required by Marpol Annex II

Category Y, high Viscosity and solidifying cargoes may require prewash, if not heated. These cargoes do not require a prewash if the following is complied with:

Category Y Cargoes with a melting point less than 15°C.

Discharge temperature should be at least 5°C. above melting point of the product. Example: Benzene with a melting point of 4.5°C. should be discharged with a temperature of at least 9.5°C. to avoid the prewash requirements.

Category Y Cargoes with a melting point above 15°C.

Discharge temperature must be at least 10°C. above melting point of the cargo. Example: Phenol, with a melting point of 40.9°C. should be discharged with a temperature of at least 51°C. in order to be considered not solidifying.

Category Y Cargoes with Viscosity < 50mpa at discharge temperature

The Master has to obtain the shipping document with above information from shipper when transporting such cargoes so that the products will be heated accordingly so as to avoid the prewash obligation if at all possible.

Temperature checks

When carrying heated cargoes the following parameters are to be checked regularly:

Edible oils Heating Instructions

Edible oils such as the various categories of palm oil and vegetable oils are highly viscous and require special attention during discharge. Each cargo of this type will have specific transportation and handling requirements. Shipowners should ensure that the supplier or charterer provides all the necessary information about the shipment such as specific gravity, color, moisture content, impurities, melting point and free fatty acid (FFA) content.

Heating instructions should also be detailed, and these should state the in-transit temperature, loading/ discharging temperature and the allowed daily rate of increase of temperature. Rapid heating of certain grades can cause scorching of the cargo, and overheating the cargo can promote oxidation, hydrolysis, scorching and discoloration of the cargo. Rapid heating can also cause an increase in FFA content, which causes the load to turn sour, and is used as a measure of cargo quality, especially for palm oil.

It is therefore essential to monitor the the temperature of the cargo carefully and, if increasing, raise the temperature of the shipment at a gradual pace. Proper planning is required for heating these cargoes, especially when a significant the rise in the temperature is required over a short voyage prompting a higher rate of heating. To avoid overheating or scorching, small parcels should be stowed in a tank of suitable size and the use of larger tanks, with a significant heating coil surface area should be avoided.

The crew should remember that carriage of heated edible oil cargoes into cold climates may cause the cargo vapors to solidify inside the cargo tank ventilation piping, effectively preventing the pressure in the cargo tank to equalize. It could potentially result in a catastrophic failure of the cargo tank.

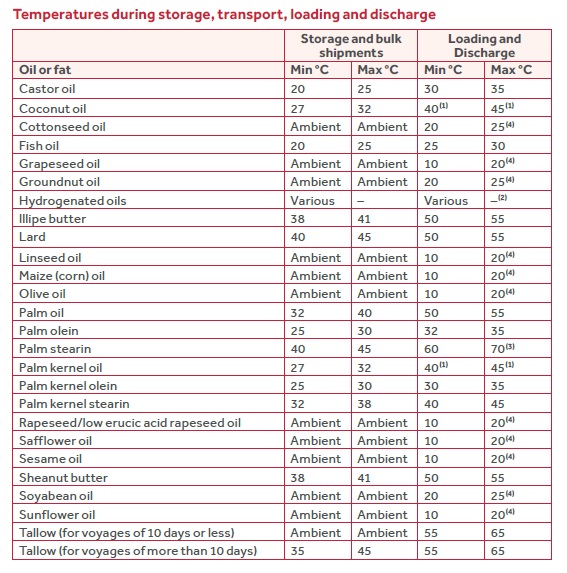

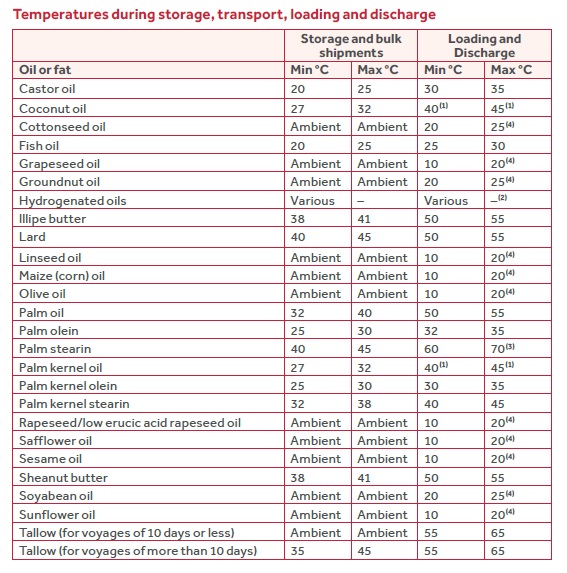

The Food and Agriculture Organization of the United Nations (FAO) recommends the practice for storage and transport of edible fats and oils (CAC/RCP 36-1987). It gives guidance on the maximum temperature required for the various grades during transit and while loading and discharging.

FAO recommended Temperatures during

storage, transport, loading and discharge for Edible Oil's

Notes to table:

(1) For heated climates, the loading and unloading temperatures for coconut oil & palm kernel oil are minimum 30°C, maximum 39°C or ambient temperature.

(2) Hydrogenated oils can differ considerably in their slip melting points, which should always be informed. It is recommended that during the voyage, the temperature should be maintained at around the declared melting point and that this should be increased before discharge to give a temperature of between 10°C and 15°C above that point to effect a clean discharge.

(3) Different grades of palm stearin may have wide variations in their slip melting points and the temperature quoted may need to be adjusted to suit specific circumstances.

(4) It is recognized that in some cases the ambient temperatures may exceed the recommended maximum figures are shown in the table.

Related Info:

Recommended temperature monitoring equipments onboard

Practical example of solving tank cleaning problems

Pre-cleaning /washing of cargo tanks

Risk & hazards of chemical contamination onboard

Cargo hoses handling ,connection and use

Checklist for handling dangerous liquid chemicals in bulk

Cargo compatibility and reactivity of various chemical cargo

Poisoning and required first aid treatment onboard

Determining presence of contaminants in chemical cargo

Chemical tanker safe mooring practice

Related Info:

Main Info pages!

Home page ||| Chemical hazards ||| Cargo planning & Stowage ||| Cargo loading ||| Cargo documents ||| Safe stability ||| Cargo care ||| Preparation for unloading ||| Inert gas systems |||Gas freeing ||| Nitrogen handling ||| Chemical handling Safe practice |||Handling equipments ||| Cargo & Ballast pumps ||| Cargo tanks |||Tank cleaning |||Special cargoes |||Spills emergencies |||Fire protection

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.

The heating instructions may contain any, or all, of the following:

- Minimum and maximum temperature during the voyage

- Minimum and maximum temperature during discharge

- Maximum temperature of adjacent cargo

- Heating medium (when loading edible oils only steam and / or hot water should be utilised as the heating medium in coils / heat exchangers. Thermal oil should not be used as a heating medium for edible oils)

- Maximum temperature of the heating medium

- The maximum possible temperature increase per unit of time: delta T°C/hour

Unintended heating

The risk of heating a cargo, which should not be heated, must be eliminated. An ‘unintended heating’ of a cargo can not only influence the quality of the cargo, but can endanger the crew, the vessel and the environment, e.g. lifetime of an inhibitor can be shortened drastically by unintended heating and a monomeric cargo such as styrene monomer can polymerise.

In order to prevent unintended heating of cargoes that do not require heating the following preventive measures should be taken:

- Blank the supply and return of the heating coils

- When heat is supplied to other tanks, check manually the supply and return of the tanks that do not require heating. Maintain a log of temperatures of tanks being heated along with surrounding tanks on TNK08.

- Do not stow heated cargo adjacent to cargoes that do not require heating Beware of hot wash of adjacent besides cargo not requiring heating

Heating required by Marpol Annex II

Category Y, high Viscosity and solidifying cargoes may require prewash, if not heated. These cargoes do not require a prewash if the following is complied with:

Category Y Cargoes with a melting point less than 15°C.

Discharge temperature should be at least 5°C. above melting point of the product. Example: Benzene with a melting point of 4.5°C. should be discharged with a temperature of at least 9.5°C. to avoid the prewash requirements.

Category Y Cargoes with a melting point above 15°C.

Discharge temperature must be at least 10°C. above melting point of the cargo. Example: Phenol, with a melting point of 40.9°C. should be discharged with a temperature of at least 51°C. in order to be considered not solidifying.

Category Y Cargoes with Viscosity < 50mpa at discharge temperature

The Master has to obtain the shipping document with above information from shipper when transporting such cargoes so that the products will be heated accordingly so as to avoid the prewash obligation if at all possible.

Temperature checks

When carrying heated cargoes the following parameters are to be checked regularly:

- Temperature of the cargo at 3 levels

- Inflow temperature of the heating medium (or steam pressure)

- Outflow temperature of the heating medium (or steam pressure)

Edible oils Heating Instructions

Edible oils such as the various categories of palm oil and vegetable oils are highly viscous and require special attention during discharge. Each cargo of this type will have specific transportation and handling requirements. Shipowners should ensure that the supplier or charterer provides all the necessary information about the shipment such as specific gravity, color, moisture content, impurities, melting point and free fatty acid (FFA) content.

Heating instructions should also be detailed, and these should state the in-transit temperature, loading/ discharging temperature and the allowed daily rate of increase of temperature. Rapid heating of certain grades can cause scorching of the cargo, and overheating the cargo can promote oxidation, hydrolysis, scorching and discoloration of the cargo. Rapid heating can also cause an increase in FFA content, which causes the load to turn sour, and is used as a measure of cargo quality, especially for palm oil.

It is therefore essential to monitor the the temperature of the cargo carefully and, if increasing, raise the temperature of the shipment at a gradual pace. Proper planning is required for heating these cargoes, especially when a significant the rise in the temperature is required over a short voyage prompting a higher rate of heating. To avoid overheating or scorching, small parcels should be stowed in a tank of suitable size and the use of larger tanks, with a significant heating coil surface area should be avoided.

The crew should remember that carriage of heated edible oil cargoes into cold climates may cause the cargo vapors to solidify inside the cargo tank ventilation piping, effectively preventing the pressure in the cargo tank to equalize. It could potentially result in a catastrophic failure of the cargo tank.

The Food and Agriculture Organization of the United Nations (FAO) recommends the practice for storage and transport of edible fats and oils (CAC/RCP 36-1987). It gives guidance on the maximum temperature required for the various grades during transit and while loading and discharging.

FAO recommended Temperatures during

storage, transport, loading and discharge for Edible Oil's

Notes to table:

(1) For heated climates, the loading and unloading temperatures for coconut oil & palm kernel oil are minimum 30°C, maximum 39°C or ambient temperature.

(2) Hydrogenated oils can differ considerably in their slip melting points, which should always be informed. It is recommended that during the voyage, the temperature should be maintained at around the declared melting point and that this should be increased before discharge to give a temperature of between 10°C and 15°C above that point to effect a clean discharge.

(3) Different grades of palm stearin may have wide variations in their slip melting points and the temperature quoted may need to be adjusted to suit specific circumstances.

(4) It is recognized that in some cases the ambient temperatures may exceed the recommended maximum figures are shown in the table.

Related Info:

Recommended temperature monitoring equipments onboard

Practical example of solving tank cleaning problems

Pre-cleaning /washing of cargo tanks

Risk & hazards of chemical contamination onboard

Cargo hoses handling ,connection and use

Checklist for handling dangerous liquid chemicals in bulk

Cargo compatibility and reactivity of various chemical cargo

Poisoning and required first aid treatment onboard

Determining presence of contaminants in chemical cargo

Chemical tanker safe mooring practice

Related Info:

-

Edible oils Heating Instructions

Heating instructions should also be detailed, and these should state the in-transit temperature, loading/ discharging temperature and the allowed daily rate of increase of temperature. Rapid heating of certain grades can cause scorching of the cargo, and overheating the cargo can promote oxidation, hydrolysis, scorching and discoloration of the cargo. Rapid heating can also cause an increase in FFA content, which causes the load to turn sour, and is used as a measure of cargo quality, especially for palm oil. -

What is putrefaction process of liquid chemicals ?

Most animal and vegetable oils undergo decomposition over time, a natural process known as putrefaction (going off), that generates obnoxious and toxic vapours and depletes the oxygen in the tank. Tanks that have contained such products must be carefully ventilated and the atmosphere tested prior to tank entry . ..... -

Carriage of inhibited flammable chemical products in cargo tanks

In certain conditions of heat, pressure and in the presence of Oxygen, some chemical cargo types can become viscous and possibly solid and dense in nature. This self reaction can cause some cargoes , especially in the presence of high temperatures and Oxygen, to begin an exothermic reaction, becoming self heating and rapidly expanding which may result in possibly disastrous consequences for the vessel. -

Cargo sampling safety precautions

Cargo samples are evidence of the condition of the product during the various phases of transport (storage at terminal, arriving on board, loading, passage, discharging). This procedure describes sample-taking procedures and the legal background. Suitable PPE is to be worn when taking samples. Sample bottle to be flushed prior collecting sample. ..... -

Cargo segregation requirement for chemical tankers

In the case of two or more liquid chemical cargoes which react with one another in a hazardous manner, segregation must be done The product data sheets, together with the BCH/IBC Codes are to be studies carefully to determine the compatibility restrictions when carrying different groups of cargoes. -

How to avoid solidification in cargo tanks ?

Solidification in the cargo tanks can occur when solidifying cargoes are stowed adjacent to “cold cargoes” or cold ballast water in adjacent spaces. Tank bottoms must therefore always be checked for hard factions especially when carrying vegetable and animal oils, at regular intervals throughout the voyage and always prior to arrival in the discharge port. -

Cargo compatibility and reactivity of various chemical cargo

Transporting of dangerous and noxious liquid chemicals in bulk involved various risk factors. Between some chemicals violent reactions may occur if the chemicals are mixed in certain proportions. The result may possibly be an eruption and tank rupture. Such an occurrance must be prevented. Water may also have to be considered in this respect. -

Determining presence of contaminants

in chemical cargo

To maintain product quality onboard modern chemical tankers any contaminants in the cargo need to be observed. Following guideline may be useful determining various product contaminants in noxious liquid chemicals. -

Ship shore cargo connection safe method

The connection at the manifold of hoses or metal cargo arms for cargo handling is the primary cargo connection between ship and shore, and it is essential that both parties take proper care preparing for the connection. Flange faces, gaskets and seals used at this point should be clean and in good condition. Minimum standards for hoses are laid down in the IBC Code. The hoses should be in good condition and installed with gaskets which are suitable for the chemical product to be handled. -

Venting of cargo tanks safety procedure

Cargo tanks of a chemical tanker are required to be provided with venting systems to prevent both over and under pressurisation of the tank. Two types of venting system are specified by the Code, namely “open” and “controlled”. -

Ship to ship transfer operation

The ship to ship (STS) transfer of cargoes carried on chemical tankers is a frequent operation, and the following article addresses some special safety aspects of the preparations and procedures that may be found necessary for STS operations. -

Ship shore safety checklist while alongside a terminal

Due regard should be given to the need for adequate fendering arrangements. Ships should remain adequately secured in their moorings. Alongside piers or quays, ranging of the ship should be prevented by keeping all mooring lines taut: attention should be given to the movement of the ship caused by wind, currents, tides or passing ships and the operation in progress. Wire ropes and fibre ropes should not be used together in the same direction (i.e. breasts, springs, head or stern) because of the difference in their elastic properties. -

Cargo compatibility chart for handling dangerous liquid chemicals in bulk

Determine the group numbers of the two cargoes by referring to the alphabetical listing of cargoes and the corresponding groups. Many cargoes are listed under their parent names: unless otherwise indicated, isomers or mixtures of isomers of a particular cargo are assigned to the same group. - Cargo handling safe practice for chemical products

Check cargo hoses to see that they have not deteriorated, that flange connections are intact, that there is an electrical bond between hose flanges and that the working pressure for the hose is marked on it. If there is any doubt about the hose's condition, find out when the hose was last pressure tested . -

Risk with noxious liquid cargo contact

Different chemicals affect the human body in many different ways. A general information and some practical advice are available in Appendix,7, of "Medical first aid guide for use in accidents involving dangerous goods" published by IMO, WHO and ILO ref (36). -

How take a sample of noxious liquid cargo ?

Cargo samples are evidence of the condition of the product during the various phases of transport (storage at terminal, arriving on board, loading, passage, discharging).For protection against possible cargo claims it is very important that cargo sampling is correctly carried out.

Main Info pages!

Home page ||| Chemical hazards ||| Cargo planning & Stowage ||| Cargo loading ||| Cargo documents ||| Safe stability ||| Cargo care ||| Preparation for unloading ||| Inert gas systems |||Gas freeing ||| Nitrogen handling ||| Chemical handling Safe practice |||Handling equipments ||| Cargo & Ballast pumps ||| Cargo tanks |||Tank cleaning |||Special cargoes |||Spills emergencies |||Fire protection

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.