Chemical tankers guideline of ship to ship transfer

The ship to ship (STS) transfer of cargoes carried on chemical tankers is a frequent operation, and the following article

addresses some special safety aspects of the preparations and procedures that may be found necessary for STS operations.

The guidance covers cargo transfer operations in open waters and roadsteads, either between two chemical carriers, or

between a chemical carrier and barges. It is not intended to cover discharge to a barge from a chemical carrier already at a

terminal, because that is considered to be normal cargo handling under the supervision and control of the port or terminal

authorities.<

Below guide provide advices about special

equipment necessary, and preparation of contingency plans for dealing with emergencies. In general, observance of the

procedures followed when handling cargo alongside a terminal will ensure safe ship to ship transfers. However, an important

additional task is careful pre-planning of the operation, noting instances where shore provision of materials or labour for

handling equipment is normal terminal practice, and identifying on board or external sources of material or personnel to

perform those duties during the ship to ship operation.

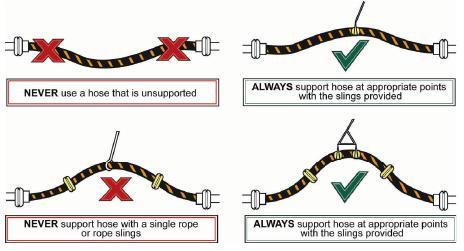

Fig:Cargo hose safety

Responsibility

In general, it is the responsibility of the ships' operators and agents to obtain any permission necessary for a ship to ship transfer operation, especially if the transfer area is within the jurisdiction of a port authority.

The general principles of a transfer, the area in which the transfer will take place, and the compatibility of the ships should follow the advice in the STS Guide, with safety always the primary consideration.

Ship operators or the local agent should advise a master about documentation requirements, especially customs documentation, well in advance of the transfer. It is normal for the quantity transferred to be agreed between masters of both ships in accordance with operator's instructions.

When preparing for a ship to ship transfer the two masters involved should agree at the earliest opportunity on every aspect of the transfer procedure, and agree which person will be in overall advisory control of the operation (this may be one of them or an experienced STS superintendent). At all times, however, each master will remain fully responsible for the safety of his own ship, its crew and its cargo, and must not permit safety to be jeopardised.

Connnunications

The STS Guide gives advice on establishing communications at the earliest opportunity, and provides an example of an initial voyage instruction. Satisfactory communication between the two ships involved is an essential requirement for a successful ship to ship transfer operation. Neither approach and mooring, nor unmooring, should be attempted until satisfactory communications are established, and if during cargo operations there is a breakdown of communications on either ship, all operations should be suspended until they are satisfactorily restored.

Navigational warnings

The person with overall advisory control should arrange for broadcast of a navigational warning about the transfer, as described in the STS Guide, and should arrange for its cancellation on completion of the operation.

Weather conditions and limitation

It is impracticable to lay down the limits of weather conditions under which STS transfer operations can safely be carried out. All available weather forecasts for the area should be obtained before the operation begins. Thus any decision to proceed will be taken in the light of best available knowledge.

Pre-transfer preparations on each ship

Preparations on each ship in readiness for the operation, the approach of the ships to each other, berthing and mooring of the ships and safety procedures when alongside, are all well described in the STS Guide. When preparing cargo loading and discharging plans, due regard should be given to ensuring that adequate stability is maintained, hull stresses remain within sea-going limits, and that free surface effects are kept to a minimum throughout.

Remember that normal shore resources will not be available and that prior assessment will help to avoid incorrect decisions that could compound an emergency and increase the peril for one or both ships.

The cargo operation should be planned and agreed between the two ships, and should include information on the following, where applicable:

1. Quantity of each grade of cargo to be transferred, and the sequence of grades.

2. Cargo data from data sheets, and copies of the data sheets if available.

3. Details of cargo transfer system to be used, number of pumps and maximum pressure.

4. Initial, maximum and topping off pumping rates. The discharging ship should be informed by the receiving ship of the flow rates required for each of the different phases of the cargo operation.

5. Notice of rate change, and transfer shutdown procedures. If variations in transfer rate subsequently become necessary due to circumstances on one ship, the other should be advised accordingly.

6. Emergency and spill containment procedures.

7. Watch or shift arrangements.

8. Critical stages of the operation.

9. Local and government rules that apply to the transfer.

Cargo transfer operations

When the two ships are securely moored, and before cargo transfer commences, the pre-transfer checks should be satisfactorily completed . In addition, attention should be given to completion, as far as practicable, of the appropriate Ship/Shore Safety Checklist .

Hose strings should be of sufficient length to avoid over-stressing and chafing throughout the cargo transfer. To establish the correct hose length, changes in relative freeboard and ship movement must be taken into account. Only hoses in good condition and suitable for the cargo to be transferred should be used. The agreed transfer rate should not exceed the manufacturer's recommended flow rates for the cargo hoses.

Vapour return and vapour balance between ships during an STS operation can be problematic. Its main advantage will be to limit the need for vapour release to atmosphere, and crew exposure to the vapour. But attention must be given to provision of a flame arresting arrangement. For some cargoes-specified in the IMO Codes, vapour return is mandatory, and STS operations will be dependent on provision of correct vapour return equipment.

Throughout cargo operations, the discharging ship and the receiving ship should each station a responsible person at the cargo manifold area to observe the hoses and to check for leaks. In addition, throughout the cargo transfer, the discharging ship should station a responsible person equipped with a portable radio at or near the cargo pump controls to take action as required. Regular transfer rate checks and comparisons should be made between the two ships, and the results logged. Any differences or anomalies revealed should be carefully checked, and if necessary cargo operations should be suspended until the differences are resolved.

During cargo transfer, appropriate ballast operations should be performed on both ships in order to minimise extreme differences in freeboard ' and to avoid excessive trim by the stern. Listing of either ship should be avoided, except as required for cargo tank draining on the discharging ship.

Regardless of the type of ship, any ballast which is discharged overboard should be clean. All other ballast should be retained on board or transferred to the discharging ship.

Completion of cargo transfer

After completion of cargo transfer, all hoses should be drained into the receiving ship prior to disconnecting. Disconnecting of cargo hoses should receive careful attention, as it is a procedure not usually undertaken by ship's personnel. Cargo manifolds and cargo hoses should be securely blanked. Relevant authorities, if any, should be informed of completion of cargo transfer and the anticipated time of unmooring. Any navigational warning issued should be cancelled.

Related Info:

Ship to ship transfer guideline using VEC systems

Cargo unloading operation safety precautions

Liaison between ship and shore

Preparation for cargo operation

Preparing a cargo tank atmosphere

Controlling the atmosphere in cargo tanks with nitrogen supplied from shore

Ship shore safety checklist while alongside a terminal

Cargo handling safe practice for chemical products

Cargo compatibility and reactivity of various chemical cargo

Poisoning and required first aid treatment onboard

Determining presence of contaminants in chemical cargo

Checklist for handling dangerous liquid chemicals in bulk

Ship shore safety checklist while alongside a terminal

Isolation of cargo tanks and piping systems

Ship shore cargo connection safe method

Venting of cargo tanks safety procedure

Ship to ship transfer operation

Controlling the atmosphere in cargo tanks with nitrogen supplied from shore

Effects of Tugs and other craft alongside chemical tankers

Primary means of cargo connection between ship and shore

Means of access (gangways or accommodation ladders) safety precautions

Ship/Shore Safety Checklist

How to prepare a cargo loading / discharge plan ?

Technical readiness prior loading operations

Voyage planning and related considerations

Cargo sampling safety precautions

Cargo calculation

Signing a bill of lading and related guideline

Preparation for cargo operation

Preparing a cargo tank atmosphere

Cargo unloading operation safety precautions

Liaison between ship and shore

How to prevent cargo pipeline leakage

Ship shore safety checklist while alongside a terminal

Reference publications

Other Info:

Voyage planning and related considerations

Preparation for cargo operation

Preparing a cargo tank atmosphere

Cargo unloading operation safety precautions

Liaison between ship and shore

Cargo line leakage countermeasures

Checklist for handling dangerous liquid chemicals in bulk

Recommended temperature monitoring equipments onboard

Practical example of solving tank cleaning problems

Pre-cleaning /washing of cargo tanks

Risk & hazards of chemical contamination onboard

Cargo compatibility and reactivity of various chemical cargo

Poisoning and required first aid treatment onboard

Chemical tanker safe mooring practice

Determining presence of contaminants in chemical cargo

How to avoid solidification in cargo tanks ?

Cargo segregation requirement for chemical tankers

How to arrange disposal of tank cleaning waste ?

Restrictions on discharge cargo residue into sea

Retention of slops on chemical tankers

Vapour emission control requirement for chemical tankers

Handling self reactive chemicals

Handling of toxic chemical cargoes

Pre-loading meeting safety consideration

How to determine chemical cargo temperatures at different level ?

How to take cargo samples ?

How to avoid solidification in cargo tanks ?

Cargo line clearance requirement for chemical tankers

How to arrange disposal of tank cleaning waste ?

Care of cargo pums - risk of pump overload or underload

Main Info pages!

Home page ||| Chemical hazards ||| Cargo planning & Stowage ||| Cargo loading ||| Cargo documents ||| Safe stability ||| Cargo care ||| Preparation for unloading ||| Inert gas systems |||Gas freeing ||| Nitrogen handling ||| Chemical handling Safe practice |||Handling equipments ||| Cargo & Ballast pumps ||| Cargo tanks |||Tank cleaning |||Special cargoes |||Spills emergencies |||Fire protection

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.

Fig:Cargo hose safety

In general, it is the responsibility of the ships' operators and agents to obtain any permission necessary for a ship to ship transfer operation, especially if the transfer area is within the jurisdiction of a port authority.

The general principles of a transfer, the area in which the transfer will take place, and the compatibility of the ships should follow the advice in the STS Guide, with safety always the primary consideration.

Ship operators or the local agent should advise a master about documentation requirements, especially customs documentation, well in advance of the transfer. It is normal for the quantity transferred to be agreed between masters of both ships in accordance with operator's instructions.

When preparing for a ship to ship transfer the two masters involved should agree at the earliest opportunity on every aspect of the transfer procedure, and agree which person will be in overall advisory control of the operation (this may be one of them or an experienced STS superintendent). At all times, however, each master will remain fully responsible for the safety of his own ship, its crew and its cargo, and must not permit safety to be jeopardised.

Connnunications

The STS Guide gives advice on establishing communications at the earliest opportunity, and provides an example of an initial voyage instruction. Satisfactory communication between the two ships involved is an essential requirement for a successful ship to ship transfer operation. Neither approach and mooring, nor unmooring, should be attempted until satisfactory communications are established, and if during cargo operations there is a breakdown of communications on either ship, all operations should be suspended until they are satisfactorily restored.

Navigational warnings

The person with overall advisory control should arrange for broadcast of a navigational warning about the transfer, as described in the STS Guide, and should arrange for its cancellation on completion of the operation.

Weather conditions and limitation

It is impracticable to lay down the limits of weather conditions under which STS transfer operations can safely be carried out. All available weather forecasts for the area should be obtained before the operation begins. Thus any decision to proceed will be taken in the light of best available knowledge.

Pre-transfer preparations on each ship

Preparations on each ship in readiness for the operation, the approach of the ships to each other, berthing and mooring of the ships and safety procedures when alongside, are all well described in the STS Guide. When preparing cargo loading and discharging plans, due regard should be given to ensuring that adequate stability is maintained, hull stresses remain within sea-going limits, and that free surface effects are kept to a minimum throughout.

Remember that normal shore resources will not be available and that prior assessment will help to avoid incorrect decisions that could compound an emergency and increase the peril for one or both ships.

The cargo operation should be planned and agreed between the two ships, and should include information on the following, where applicable:

1. Quantity of each grade of cargo to be transferred, and the sequence of grades.

2. Cargo data from data sheets, and copies of the data sheets if available.

3. Details of cargo transfer system to be used, number of pumps and maximum pressure.

4. Initial, maximum and topping off pumping rates. The discharging ship should be informed by the receiving ship of the flow rates required for each of the different phases of the cargo operation.

5. Notice of rate change, and transfer shutdown procedures. If variations in transfer rate subsequently become necessary due to circumstances on one ship, the other should be advised accordingly.

6. Emergency and spill containment procedures.

7. Watch or shift arrangements.

8. Critical stages of the operation.

9. Local and government rules that apply to the transfer.

Cargo transfer operations

When the two ships are securely moored, and before cargo transfer commences, the pre-transfer checks should be satisfactorily completed . In addition, attention should be given to completion, as far as practicable, of the appropriate Ship/Shore Safety Checklist .

Hose strings should be of sufficient length to avoid over-stressing and chafing throughout the cargo transfer. To establish the correct hose length, changes in relative freeboard and ship movement must be taken into account. Only hoses in good condition and suitable for the cargo to be transferred should be used. The agreed transfer rate should not exceed the manufacturer's recommended flow rates for the cargo hoses.

Vapour return and vapour balance between ships during an STS operation can be problematic. Its main advantage will be to limit the need for vapour release to atmosphere, and crew exposure to the vapour. But attention must be given to provision of a flame arresting arrangement. For some cargoes-specified in the IMO Codes, vapour return is mandatory, and STS operations will be dependent on provision of correct vapour return equipment.

Throughout cargo operations, the discharging ship and the receiving ship should each station a responsible person at the cargo manifold area to observe the hoses and to check for leaks. In addition, throughout the cargo transfer, the discharging ship should station a responsible person equipped with a portable radio at or near the cargo pump controls to take action as required. Regular transfer rate checks and comparisons should be made between the two ships, and the results logged. Any differences or anomalies revealed should be carefully checked, and if necessary cargo operations should be suspended until the differences are resolved.

During cargo transfer, appropriate ballast operations should be performed on both ships in order to minimise extreme differences in freeboard ' and to avoid excessive trim by the stern. Listing of either ship should be avoided, except as required for cargo tank draining on the discharging ship.

Regardless of the type of ship, any ballast which is discharged overboard should be clean. All other ballast should be retained on board or transferred to the discharging ship.

Completion of cargo transfer

After completion of cargo transfer, all hoses should be drained into the receiving ship prior to disconnecting. Disconnecting of cargo hoses should receive careful attention, as it is a procedure not usually undertaken by ship's personnel. Cargo manifolds and cargo hoses should be securely blanked. Relevant authorities, if any, should be informed of completion of cargo transfer and the anticipated time of unmooring. Any navigational warning issued should be cancelled.

Related Info:

Ship to ship transfer guideline using VEC systems

Cargo unloading operation safety precautions

Liaison between ship and shore

Preparation for cargo operation

Preparing a cargo tank atmosphere

Controlling the atmosphere in cargo tanks with nitrogen supplied from shore

Ship shore safety checklist while alongside a terminal

Cargo handling safe practice for chemical products

Cargo compatibility and reactivity of various chemical cargo

Poisoning and required first aid treatment onboard

Determining presence of contaminants in chemical cargo

Checklist for handling dangerous liquid chemicals in bulk

Ship shore safety checklist while alongside a terminal

Isolation of cargo tanks and piping systems

Ship shore cargo connection safe method

Venting of cargo tanks safety procedure

Ship to ship transfer operation

Controlling the atmosphere in cargo tanks with nitrogen supplied from shore

Effects of Tugs and other craft alongside chemical tankers

Primary means of cargo connection between ship and shore

Means of access (gangways or accommodation ladders) safety precautions

Ship/Shore Safety Checklist

How to prepare a cargo loading / discharge plan ?

Technical readiness prior loading operations

Voyage planning and related considerations

Cargo sampling safety precautions

Cargo calculation

Signing a bill of lading and related guideline

Preparation for cargo operation

Preparing a cargo tank atmosphere

Cargo unloading operation safety precautions

Liaison between ship and shore

How to prevent cargo pipeline leakage

Ship shore safety checklist while alongside a terminal

Reference publications

- IBC Code / BCH code

- International Safety Guide for Oil Tankers and Terminals (ISGOTT)

- ICS Chemical Tanker Safety Guide

- Ship’s “Procedure and Arrangements Manual” (Approved by Class)

- Certificate of Fitness for the Carriage of Dangerous Chemicals in Bulk

- Ship’s “VEC System Operational Manual” (Approved by Class)

- Ship to Ship Transfer Guide (Petroleum)

- Tank Cleaning Manual

Other Info:

Voyage planning and related considerations

Preparation for cargo operation

Preparing a cargo tank atmosphere

Cargo unloading operation safety precautions

Liaison between ship and shore

Cargo line leakage countermeasures

Checklist for handling dangerous liquid chemicals in bulk

Recommended temperature monitoring equipments onboard

Practical example of solving tank cleaning problems

Pre-cleaning /washing of cargo tanks

Risk & hazards of chemical contamination onboard

Cargo compatibility and reactivity of various chemical cargo

Poisoning and required first aid treatment onboard

Chemical tanker safe mooring practice

Determining presence of contaminants in chemical cargo

How to avoid solidification in cargo tanks ?

Cargo segregation requirement for chemical tankers

How to arrange disposal of tank cleaning waste ?

Restrictions on discharge cargo residue into sea

Retention of slops on chemical tankers

Vapour emission control requirement for chemical tankers

Handling self reactive chemicals

Handling of toxic chemical cargoes

Pre-loading meeting safety consideration

How to determine chemical cargo temperatures at different level ?

How to take cargo samples ?

How to avoid solidification in cargo tanks ?

Cargo line clearance requirement for chemical tankers

How to arrange disposal of tank cleaning waste ?

Care of cargo pums - risk of pump overload or underload

Main Info pages!

Home page ||| Chemical hazards ||| Cargo planning & Stowage ||| Cargo loading ||| Cargo documents ||| Safe stability ||| Cargo care ||| Preparation for unloading ||| Inert gas systems |||Gas freeing ||| Nitrogen handling ||| Chemical handling Safe practice |||Handling equipments ||| Cargo & Ballast pumps ||| Cargo tanks |||Tank cleaning |||Special cargoes |||Spills emergencies |||Fire protection

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.