Reason of cargo line leakage & procedure for chemical tankers

There are many reason that may lead to cargo line failure on board chemical tanker.

Galvanic corrosion in the cargo and stripping pipelines may cause several leakage. One of the sources of such corrosion in pipelines

is variation in corrosion resistance at adjacent points in the piping. These variations are caused by inadequate surface preparation of

the interior of the piping following welding during the vessel’s construction.

The weld seam and the adjacent heat affected zone will suffer from thermal oxidation, seen as dark oxide bands. At these areas the protective chromium oxide layer cannot adequately form, and the resistance to corrosion will be less than that of the surrounding stainless steel not affected by welding.

The weld seam and the adjacent heat affected zone will suffer from thermal oxidation, seen as dark oxide bands. At these areas the protective chromium oxide layer cannot adequately form, and the resistance to corrosion will be less than that of the surrounding stainless steel not affected by welding.

Below is some example of pipeline corrosion

Diagnosis

Presence of chromium in quantities greater than 12 weight percent. The ability to form chromium oxide in the weld region must be maintained. Some stainless steels are sold containing as little as 9 weight percent chromium and will rust at ambient temperatures.

Stainless steels are subject to localized corrosive attack. The prevention of corrosive attack is one of the concerns when selecting base metal, filler metal and welding procedures when fabricating components from stainless steel.

Discoloration of the heat-affected zone is due to absence or lack of use of an inert gas during welding or pickling. Susceptibility of steel to liquation cracking. Occurrence of Cracks in various regions of the weld in the underlying weld metal or adjacent heat-affected zone. Problems associated with discoloration of stainless steel welds are:

Recommendation To carryout chemical cleaning (Pickling) of the deck cargo lines and cargo stripping lines. Incomplete or substandard welding within the piping welding cannot be corrected by chemical means.

Circulating aqueous solutions of degreasing compounds, fresh water, aqueous solutions of pickling acids, and again fresh water, through the piping. In order to achieve this, it was necessary to divide the work into 4 “systems”. Each system, or loop, comprised one or more cargo lines and the associated stripping lines.

Results:

Fig:line 1 after treatment

Line 1 (after treatment) – Cleaning and pickling successful

Fig:line 4 after treatment

Line 4 (after treatment) – Pickling successful, some evidence of trapped air pockets caused by vessel trim Conclusion: The cargo and stripping lines of the ships were successfully chemically cleaned. Removal of contaminants such as heavy oxides enables entire stainless steel surface to have a uniform character in terms of chemical composition. Cargo lines shall be thoroughly cleaned with FW water and / or steam each time tank cleaning is carried out to avoid such pipeline corrosion resulting in leakages.

Related Info:

Other Info pages

Voyage planning and related considerations

Preparation for cargo operation

Preparing a cargo tank atmosphere

Cargo unloading operation safety precautions

Liaison between ship and shore

Cargo line leakage countermeasures

Checklist for handling dangerous liquid chemicals in bulk

Recommended temperature monitoring equipments onboard

Practical example of solving tank cleaning problems

Pre-cleaning /washing of cargo tanks

Risk & hazards of chemical contamination onboard

Cargo compatibility and reactivity of various chemical cargo

Poisoning and required first aid treatment onboard

Chemical tanker safe mooring practice

Determining presence of contaminants in chemical cargo

Handling various grade liquid chemicals during loading

How to prepare a cargo loading or discharge program ?

How to avoid solidification in cargo tanks ?

Cargo segregation requirement for chemical tankers

How to take cargo samples ?

How to arrange disposal of tank cleaning waste ?

Restrictions on discharge cargo residue into sea

Retention of slops on chemical tankers

Vapour emission control requirement for chemical tankers

Handling self reactive chemicals

Handling of toxic chemical cargoes

Main Info pages!

Home page ||| Chemical hazards ||| Cargo planning & Stowage ||| Cargo loading ||| Cargo documents ||| Safe stability ||| Cargo care ||| Preparation for unloading ||| Inert gas systems |||Gas freeing ||| Nitrogen handling ||| Chemical handling Safe practice |||Handling equipments ||| Cargo & Ballast pumps ||| Cargo tanks |||Tank cleaning |||Special cargoes |||Spills emergencies |||Fire protection

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.

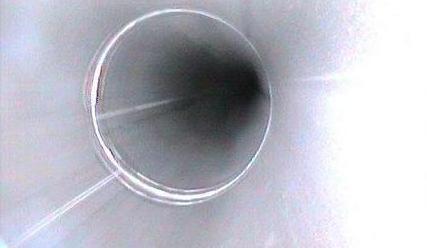

- Line 1– Extensive rust spots, most likely caused by free iron/oxides trapped on pipeline surfaces

- Line 2– Evidence that at one time the piping had been half submerged in a pickling acid, with the lower half circle of weld seam pickled and the upper half circle untreated

- Line 3– Extensive contamination, especially near weld seams, possibly caused by free iron/oxides trapped on surfaces

- Line 4 – Weld seams contaminated with significant corrosion products

Fig:line 1 before treatment

Fig:line 2 before treatment

Fig:line 3 before treatment

Fig:line 4 before treatment

Diagnosis

Presence of chromium in quantities greater than 12 weight percent. The ability to form chromium oxide in the weld region must be maintained. Some stainless steels are sold containing as little as 9 weight percent chromium and will rust at ambient temperatures.

Stainless steels are subject to localized corrosive attack. The prevention of corrosive attack is one of the concerns when selecting base metal, filler metal and welding procedures when fabricating components from stainless steel.

Discoloration of the heat-affected zone is due to absence or lack of use of an inert gas during welding or pickling. Susceptibility of steel to liquation cracking. Occurrence of Cracks in various regions of the weld in the underlying weld metal or adjacent heat-affected zone. Problems associated with discoloration of stainless steel welds are:

- Reduction in Corrosion resistance.

- Absorption of chlorides causing a corrosive micro environment.

- Low amounts of chlorides causing chloride stress-corrosion cracking and pitting.

Recommendation To carryout chemical cleaning (Pickling) of the deck cargo lines and cargo stripping lines. Incomplete or substandard welding within the piping welding cannot be corrected by chemical means.

Circulating aqueous solutions of degreasing compounds, fresh water, aqueous solutions of pickling acids, and again fresh water, through the piping. In order to achieve this, it was necessary to divide the work into 4 “systems”. Each system, or loop, comprised one or more cargo lines and the associated stripping lines.

Results:

Fig:line 1 after treatment

Fig:line 4 after treatment

Related Info:

- Cargo line leakage countermeasures

There are many reason that may lead to cargo line failure on board chemical tanker. Galvanic corrosion in the cargo and stripping pipelines may cause several leakage. One of the sources of such corrosion in pipelines is variation in corrosion resistance at adjacent points in the piping. -

Checklist for handling dangerous liquid chemicals in bulk

Is information available giving the necessary data for the safe handling of the cargo and, where applicable, is a manufacturer's inhibition certificate available? Information on the product to be handled should be available on board the ship and ashore before and during the operation. -

Recommended temperature monitoring equipments onboard

Temperature sensors are fitted so that the temperature of the cargo can be monitored, especially where required by the IBC Code. It is important to know the cargo temperature in order to be able to calculate the weight of cargo on board, and because tanks or their coatings often have a maximum temperature limit. Many cargoes are temperature sensitive, and can be damaged by overheating or if permitted to solidify. Sensors may also be fitted to monitor the temperatures of the structure around the cargo system. -

Practical example of solving tank cleaning problems

Tank cleaning is essential on-a chemical tanker, but it must be recognised as a potentially hazardous operation, and rigorous precautions should be observed throughout the process. Together with gas freeing, it is probably the most hazardous operation routinely undertaken on a chemical tanker.

Pre-cleaning /washing of cargo tanks - Pre-cleaning /washing of cargo tanks

Washing between different grades of cargo is the most common reason for tank cleaning. In most cargo sequences on chemical tankers, this cleaning may consist of no more than a simple hot or cold seawater wash. A simple water wash will disperse many types of chemicals and has been found effective between clean petroleum products such as gas oil and kerosene. - Final cleaning of cargo tanks prior loading

Method of final cleaning to be used depends on both previous cargo and cargo to be loaded. As a general rule the tanks and piping shall be completely drained of water or residues before loading. The bottom of the tanks may have to be dried up with rags. - Tank cleaning and posoning hazards

Certain substances affect the tissues locally as an irritant (cashew nut shell oil) or cause grave damage to the eyes, skin or mucous membranes (e g strong acids and caustic). Other substances may be absorbed by contact to the skin without local effects (e g nitrobenzene, aniline). - Testing of tanks and cargoes

Most common tests and checks for oil and chemical cargoes include testing tank walls for cleanliness. Testing is normally carried out by independent surveyors who, according to local practice or a written agreement in the charter party, are accepted by shipper, receiver and owner. -

Practical tank cleaning methods for various noxious liquid cargo

Tanks that may have contained monomer or drying oils should first be cleaned with sufficient cold water quantities to avoid polymerization of cargo residues. In some cases, it is necessary to employ tank cleaning chemicals, but their use is generally limited as it may be difficult to dispose of slops. -

Special tank cleaning method

If a special method involving cleaning agents is to be used, it may create an additional hazard for the crew. Shipboard procedures should ensure that personnel are familiar with, and protected from, the health hazards associated with such a method. The cleaning agents may be added to the wash water or used alone. The cleaning procedures adopted should not entail the need for personnel to enter the tank. -

Determining proper tank cleaning by acid wash method

The acid wash method is used if there is any suspicion that a cargo of aromatics may have been contaminated by a previous oil cargo. The method is also used as a check that a tank is sufficiently cleaned before loading aromatics. -

Supervision of all tank cleaning and gas freeing operations

Tank cleaning is essential on-a chemical tanker, but it must be recognised as a potentially hazardous operation, and rigorous precautions should be observed throughout the process. Together with gas freeing, it is probably the most hazardous operation routinely undertaken on a chemical tanker. -

Disposal of tank washings, slops and dirty ballast - safe method

During normal operations of a chemical carrier, the main need to dispose of chemical residues, slops or water contaminated with cargo will arise during or immediately after tank cleaning. Final disposal of slops or washwater should be in accordance with the ship's P&A Manual. Tank washings and slops may be retained on board in a slop tank, or discharged ashore or into barges. -

PV valves -function and maintenance requirements

Pressure/Vacuum valves are designed to provide protection of all cargo tanks against over/under pressure and provide for the flow of small volumes of tank atmosphere resulting from temperature variations in the cargo tank(s) and should operate in advance of the pressure/vacuum breaker, where IG system is in use.... - Deck seal, tank non return valves and tank gauging requirements

On vessels fitted with an inert gas system it is a requirement to maintain a positive seal between the cargo tanks and the inert gas generation plant this is usually accomplished by the use of a non - return valve and a Deck Water Seal... -

Loading / stress computer

This instrument is provided to supplement the stability booklet for the vessel. It allows the Officer responsible, to carry out the various complex calculations required to ensure that the ship is not overstressed or damaged during the carriage of the nominated cargoes.. -

Various cargo handling safety equipments carriage requirements

It is essential on chemical tankers that everyone knows his ship's safety equipments thoroughly prior handling noxious chemical cargo. Also the master/chief officer must assume responsibility for this. -

Vapour emission control requirement for chemical tankers

Vessels fitted with a VEC system must have an independent overfill alarm providing audible and visual warning. These are to be tested at the tank to ensure their proper operation prior to commencing loading, unless the system is provided with an electronic self-testing capability. Fixed gauging systems must be maintained in a fully operational condition at all times. ..... -

Draegar Chemical detector tubes use and reading correction guideline

These instruments, often referred to as Draeger tubes, normally function by drawing a sample of the atmosphere to be tested through a proprietary chemical reagent in a glass tube. The detecting reagent becomes progressively discoloured if a contaminant vapour is present in the sample. The length of the discoloration stain gives a measure of the concentration of the chemical vapour which can be read from the graduated scale printed on the tube. Detector tubes give an accurate indication of chemical vapour concentration, whatever the oxygen content of the mixture -

Requirements of various grade chemical cargo heating

: The voyage orders will contain heating information, if heating is required. As a rule the final heating instructions are given by the Shipper in writing to the Master / Chief Officer in the port of loading. If those written instructions are not given, the master should request them and issue a Letter of Protest if they are not received at departure. In the latter case the management office should be immediately informed. -

Recommended temperature monitoring equipments onboard

:Temperature sensors are fitted so that the temperature of the cargo can be monitored, especially where required by the IBC Code. It is important to know the cargo temperature in order to be able to calculate the weight of cargo on board, and because tanks or their coatings often have a maximum temperature limit. Many cargoes are temperature sensitive, and can be damaged by overheating or if permitted to solidify. Sensors may also be fitted to monitor the temperatures of the structure around the cargo system. -

Cargo instruments

:In order to maintain a proper control of the tank atmosphere and to check the effectiveness of gas freeing, especially prior to tank entry, several different gas measuring instruments need to be available for use. Which one to use will depend upon the type of atmosphere being measured. -

Liquid level gauges

:The accuracy required of chemical carrier level gauges is high because of the nature and value of the cargo. To limit personnel exposure to chemicals or their vapours while cargo is being handled, or during carriage at sea, the IBC Code specifies three methods of gauging the level of a liquid in a tank - open, restricted or closed -

Overflow control

:Certain cargoes require the designated tank to be fitted with a separate high level alarm to give warning before the tank becomes full. The alarm may be activated by either a float operating a switch device, a capacitive pressure transmitter, or an ultrasonic or radioactive source. The activation point is usually pre-set at 95% of tank capacity. -

Oxygen analysers

:Oxygen analysers are normally used to determine the oxygen level in the atmosphere of an enclosed space: for instance, to check that a cargo tank can be considered fully inerted, or whether a compartment is safe for entry.

Vapour detection

:Ships carrying toxic or flammable products (or both) should be equipped with at least two instruments that are designed and calibrated for testing the gases of the products carried. If the instruments are not capable of testing for both toxic concentrations and flammable concentrations, then separate sets of instruments should be provided. -

Alarm circuit

:An important feature of many modern measurement and control instruments is the ability to signal a particular situation. This can be a main operational alarm that gives an indication of a pre-set situation such as liquid level in a tank, or a malfunction alarm indicating a failure within a sensor's own operating mechanism. The designs and purposes of alarm and shutdown circuits vary widely, and their operating system may be pneumatic, hydraulic, electrical or electronic. Safe operation of plant and systems depends on the correct operation of these circuits and a knowledgeable reaction to them. - Venting of cargo tanks safety procedure

The cargo tank venting system should be set for the type of operation to be performed. Cargo vapour displaced from tanks during loading or ballasting should be vented through the installed venting system to atmosphere, except when return of the vapour to shore is required. The cargo or ballast loading rate should not exceed a rate of vapour flow within the capacity of the installed system. .....

Other Info pages

Voyage planning and related considerations

Preparation for cargo operation

Preparing a cargo tank atmosphere

Cargo unloading operation safety precautions

Liaison between ship and shore

Cargo line leakage countermeasures

Checklist for handling dangerous liquid chemicals in bulk

Recommended temperature monitoring equipments onboard

Practical example of solving tank cleaning problems

Pre-cleaning /washing of cargo tanks

Risk & hazards of chemical contamination onboard

Cargo compatibility and reactivity of various chemical cargo

Poisoning and required first aid treatment onboard

Chemical tanker safe mooring practice

Determining presence of contaminants in chemical cargo

Handling various grade liquid chemicals during loading

How to prepare a cargo loading or discharge program ?

How to avoid solidification in cargo tanks ?

Cargo segregation requirement for chemical tankers

How to take cargo samples ?

How to arrange disposal of tank cleaning waste ?

Restrictions on discharge cargo residue into sea

Retention of slops on chemical tankers

Vapour emission control requirement for chemical tankers

Handling self reactive chemicals

Handling of toxic chemical cargoes

Main Info pages!

Home page ||| Chemical hazards ||| Cargo planning & Stowage ||| Cargo loading ||| Cargo documents ||| Safe stability ||| Cargo care ||| Preparation for unloading ||| Inert gas systems |||Gas freeing ||| Nitrogen handling ||| Chemical handling Safe practice |||Handling equipments ||| Cargo & Ballast pumps ||| Cargo tanks |||Tank cleaning |||Special cargoes |||Spills emergencies |||Fire protection

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.