Handling Vegetable Oils & Animal Fats- Chemical Tanker Solutions

Edible (fatty) oils are obtained from vegetable and marine sources. Vegetable oils comprise those obtained

from the processing of seeds, e.g. sunflower oil, or of fruit, e.g. palm oil. Edible oils also include those of

animal origin such as butter oil, lard and tallow. Marine oils are obtained from fish, but differ considerably

in composition depending on the fish species.

Oils may also be categorised in relation to the extent of processing which they have undergone prior to shipment. Most are shipped in the crude state but the shipment of refined products, often described as "Refined, bleached and deodorised" (RBD), has increased considerably in recent years. Generally, refined oils are more sensitive to poor storage and handling conditions than crude oils.

Oils may also be categorised in relation to the extent of processing which they have undergone prior to shipment. Most are shipped in the crude state but the shipment of refined products, often described as "Refined, bleached and deodorised" (RBD), has increased considerably in recent years. Generally, refined oils are more sensitive to poor storage and handling conditions than crude oils.

At ambient temperature oils may be liquid, semi-solid or fully solid. The state of the oil is obviously

of importance to the shipper in view of the effect it will have on handling both at the time of loading and

at discharge. Seed oils are mainly liquid at ambient temperature and are often referred to as "soft" oils,

whereas commodities such as palm oil and coconut oil are sufficiently solid at ambient temperatures to

require some heating before being pumped to or from ship's tanks. Castor oil is an unusual seed oil in

that it is far more viscous than all other vegetable oils and, despite remaining a liquid throughout normal

temperature ranges, requires some heating prior to pumping.

Palm oil and its products, e.g. palm olein and palm stearin, form a large proportion of the oil traded, often in parcel tankers. These oils are shipped mainly from Malaysia and Indonesia, to many ports in Europe, USA and Asia. The seed oils most frequently shipped are soya, rape and sunflower, which are produced in a number of South and North American countries. In addition groundnut (peanut) oil is regularly shipped from West Africa. A by-product of palm oil refining, Palm Fatty Acid Distillate (PFAD), is another important cargo.

Although it is possible to transport refined oils over long distances without significant loss in quality, provided proper precautions are taken, oil users often prefer crude oils, as the oil can then be refined to their own specification.

There is also a growing trade in fatty acid methyl esters derived from vegetable and animal fats, which form the major constituent in biofuels.

The acid value (AV) of the liquid substance is used as a measure of quality. The acid value should not be too high as it indicates an excessively high content of FFA, which causes the load to turn sour. Fat is blended with glycerine and fatty acid. When the fat is hot, it disintegrates to free fatty acid (FFA) and glycerine (hydrolysis). An appreciation of FFA means that the cargo will become inferior in quality. In the case of palm oil cargo, its acid value mostly determines the product quality. Therefore rapid heating increases FFA content or the discoloration is nasty.

Edible Oils and Fats Contracts

FOSFA International (the Federation of Oils, Seeds and Fats Associations) concerns itself with all aspects of the international trade in oilseeds, oils and fats, providing guidance on the sea transport of such commodities.

FOSFA provides an extensive range of contracts for use in the buying and selling of oilseeds such as rape, soya and sunflower as well as edible oils and fats in bulk, together with such commodities as copra, groundnuts and palm kernels. Contracts cover all animal, vegetable and marine oils traded on CIF or FOB terms.

Details of FOSFA can be found at www.fosfa.org.

Contracts, which may be modified by agreement between the parties, provide information relating to oil quality, agreed specifications and quantities to be shipped. Particular commodity contracts, e.g. crude palm oil, will also provide a few analytical characteristics of the cargo at the time of loading and on arrival at the port of discharge. Other clauses may cover tolerances with regard to the quantity of oil delivered, the employment of superintendents for surveying and sampling, standards for the carrying vessel, the ship's tanks to be used and conditions for transhipment.

Acceptable and Banned Cargoes

Trade in vegetable and marine oils generally entails the carriage from the producer country to the user country. Since user countries are generally not shippers of edible oils, tanks may be used on return voyages for commodities other than edible oils, e.g. chemicals. The possibility of even very low-level contamination has resulted in FOSFA creating categories of non-oil cargoes to ensure that edible oil cargoes are not contaminated. Thus, the lists of "Banned Immediate Previous Cargoes" and "Acceptable Previous Cargoes" may be found on the FOSFA website. The site also links to similar lists produced by the National Institute for Oilseed Products (NIOP).

Chemicals on the Banned List are known to have adverse toxicological or carcinogenic properties and, in some cases, the banning extends to two or three cargoes carried immediately before the carriage of an edible oil cargo. Similarly, an European Union Commission Directive giving the regulations which must be followed when oils are imported into the EU can be accessed from the EU website.

Ship Suitability, Tank Coatings and Tank Cleaning

Cargo Maintenance

The range of physical properties of edible oils, particularly with respect to their tendency to solidify at ambient temperature, means that conditions for handling and storage cannot be standardised but must be considered and specified for each oil.

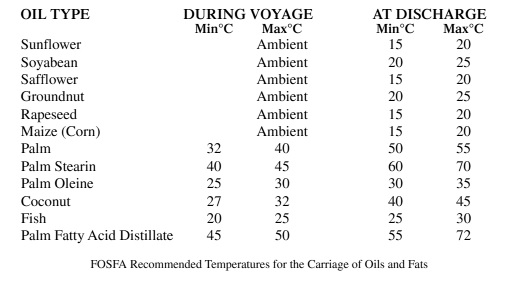

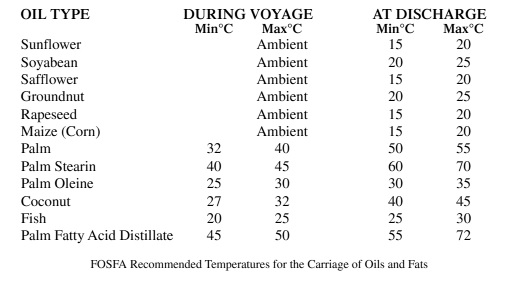

FOSFA has published a temperature regime for the handling and storage of a large number of oils, and details of the conditions adopted as suitable are given below. The sensitivity of oils to high temperature makes it essential that when oils are to be heated prior to pumping, it should be achieved with the lowest realistic temperature differential between the heating medium and oil. In consequence, extended heating times prior to discharge are likely to be necessary (where the consistency of the oil is such as to require heating).

Damage

The characteristics of an oil cargo may change while in transit and while this may appear to be damage it is often likely to be no more than a natural change. For example, after some weeks in a tank, sunflower oil may have a deposit of foots (or sediment) on the tank bottom and the oil may appear cloudy on discharge despite having been clear at the time of loading. In such circumstances it is likely that the oil has not been damaged, but a claim may be made when the appearance of the oil has changed between loading and discharge.

Recommended temperature for the carriage of fats & oils

Damage to a fatty oil cargo, leading to it being in an unsatisfactory or even unacceptable condition on discharge, may be caused by:

The crew should remember that carriage of heated edible oil cargoes into cold climates may cause the cargo vapors to solidify inside the cargo tank ventilation piping, effectively preventing the pressure in the cargo tank to equalize. It could potentially result in a catastrophic failure of the cargo tank.

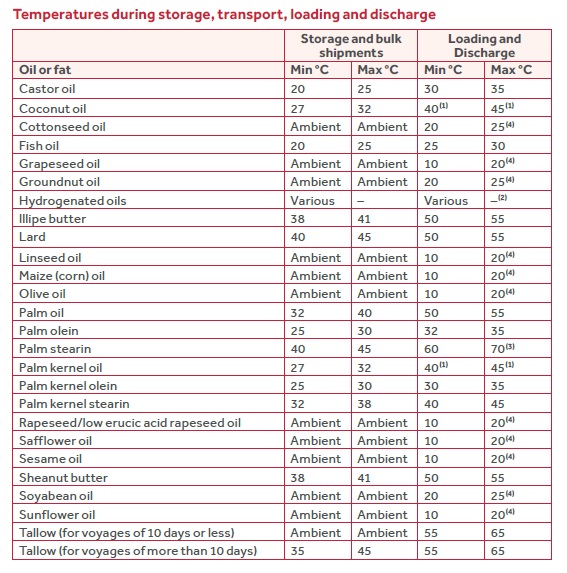

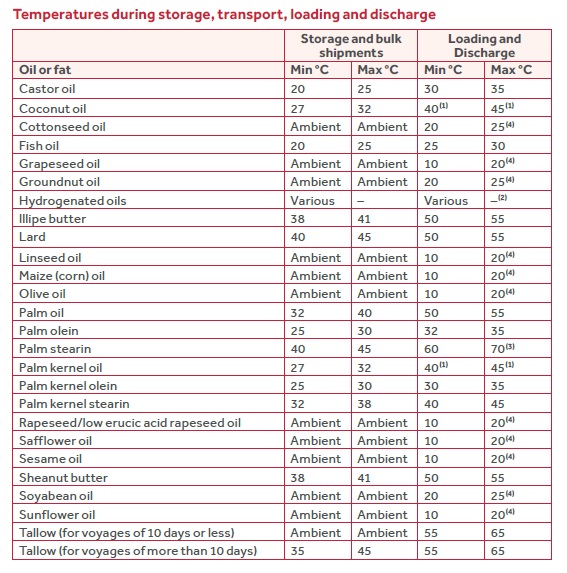

The Food and Agriculture Organization of the United Nations (FAO) recommends the practice for storage and transport of edible fats and oils (CAC/RCP 36-1987). It gives guidance on the maximum temperature required for the various grades during transit and while loading and discharging.

FAO recommended Temperatures during

storage, transport, loading and discharge for Edible Oil's

Notes to table:

Conclusion

We have summarized below some of the special chemical cargoes frequently carried onboard chemical tankers

Handling benzene & methanol safety precautions

Handling carcinogens requirements for certain chemical cargoes

Handling ACRYLONITRILE safety precautions

handling ISOCYANATES safety precautions

handling Sulfuric acid safety precautions

Handling benzene & methanol safety precautions

Requirements of various grade chemical cargo heating

Following detail pages explain all liquid chemical hazards & precautionary measures while carrying at sea.

Following reference publications provide useful guidance and international regulations for carrying hazardous chemicals at sea.

Main Info pages!

Home page ||| Chemical hazards ||| Cargo planning & Stowage ||| Cargo loading ||| Cargo documents ||| Safe stability ||| Cargo care ||| Preparation for unloading ||| Inert gas systems |||Gas freeing ||| Nitrogen handling ||| Chemical handling Safe practice |||Handling equipments ||| Cargo & Ballast pumps ||| Cargo tanks |||Tank cleaning |||Special cargoes |||Spills emergencies |||Fire protection

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.

Palm oil and its products, e.g. palm olein and palm stearin, form a large proportion of the oil traded, often in parcel tankers. These oils are shipped mainly from Malaysia and Indonesia, to many ports in Europe, USA and Asia. The seed oils most frequently shipped are soya, rape and sunflower, which are produced in a number of South and North American countries. In addition groundnut (peanut) oil is regularly shipped from West Africa. A by-product of palm oil refining, Palm Fatty Acid Distillate (PFAD), is another important cargo.

Although it is possible to transport refined oils over long distances without significant loss in quality, provided proper precautions are taken, oil users often prefer crude oils, as the oil can then be refined to their own specification.

There is also a growing trade in fatty acid methyl esters derived from vegetable and animal fats, which form the major constituent in biofuels.

The acid value (AV) of the liquid substance is used as a measure of quality. The acid value should not be too high as it indicates an excessively high content of FFA, which causes the load to turn sour. Fat is blended with glycerine and fatty acid. When the fat is hot, it disintegrates to free fatty acid (FFA) and glycerine (hydrolysis). An appreciation of FFA means that the cargo will become inferior in quality. In the case of palm oil cargo, its acid value mostly determines the product quality. Therefore rapid heating increases FFA content or the discoloration is nasty.

Edible Oils and Fats Contracts

FOSFA International (the Federation of Oils, Seeds and Fats Associations) concerns itself with all aspects of the international trade in oilseeds, oils and fats, providing guidance on the sea transport of such commodities.

FOSFA provides an extensive range of contracts for use in the buying and selling of oilseeds such as rape, soya and sunflower as well as edible oils and fats in bulk, together with such commodities as copra, groundnuts and palm kernels. Contracts cover all animal, vegetable and marine oils traded on CIF or FOB terms.

Details of FOSFA can be found at www.fosfa.org.

Contracts, which may be modified by agreement between the parties, provide information relating to oil quality, agreed specifications and quantities to be shipped. Particular commodity contracts, e.g. crude palm oil, will also provide a few analytical characteristics of the cargo at the time of loading and on arrival at the port of discharge. Other clauses may cover tolerances with regard to the quantity of oil delivered, the employment of superintendents for surveying and sampling, standards for the carrying vessel, the ship's tanks to be used and conditions for transhipment.

Acceptable and Banned Cargoes

Trade in vegetable and marine oils generally entails the carriage from the producer country to the user country. Since user countries are generally not shippers of edible oils, tanks may be used on return voyages for commodities other than edible oils, e.g. chemicals. The possibility of even very low-level contamination has resulted in FOSFA creating categories of non-oil cargoes to ensure that edible oil cargoes are not contaminated. Thus, the lists of "Banned Immediate Previous Cargoes" and "Acceptable Previous Cargoes" may be found on the FOSFA website. The site also links to similar lists produced by the National Institute for Oilseed Products (NIOP).

Chemicals on the Banned List are known to have adverse toxicological or carcinogenic properties and, in some cases, the banning extends to two or three cargoes carried immediately before the carriage of an edible oil cargo. Similarly, an European Union Commission Directive giving the regulations which must be followed when oils are imported into the EU can be accessed from the EU website.

Ship Suitability, Tank Coatings and Tank Cleaning

- Ship Suitability : Heating coils should be of stainless steel only; copper and alloys such as brass, bronze or gun metal should not be used for any part of the cargo handling system with which the cargo has contact, e.g. piping, pipe connections, pumps, valves, heating coils, etc. Tank access/cleaning hatches must be staunch and tight with suitable packing and gaskets compatible with the cargo and its carriage temperature. Cargo lines should be of stainless steel with sufficient drain valves to ensure complete clearing and draining of the system. Internal structural members in cargo tanks should be self-draining.

- Tank Coatings :

Tanks, other than those of stainless steel, are normally coated, although mild steel tanks may be employed

for short sea passages. Only coatings fit for food grade products and suitable for the carriage of the oils

or fats to be loaded should be used. Blisters or loose splits in the coating should be opened and cleaned to

ensure that no cargo residue remains. Areas of mild steel exposure in coated tanks should be minimal and

any loose scale must be removed.

Zinc silicate coating should not be used for crude oil. Specialist advice should be sought if clarification is required. - Tank Cleaning : All previous cargo residues must be removed before loading edible oil and comprehensive guidance is available in Verwey's "The Tank Cleaning Guide", 8th Edition, 2011 which provides details of the cleaning procedures for more than 400 liquid bulk commodities. Manufacturers of tank coatings and cleaning chemicals will also advise on the compatibility of individual coatings and cleaning agents. The atmosphere of a tank should always be tested before it is entered to carry out cleaning.

Cargo Maintenance

The range of physical properties of edible oils, particularly with respect to their tendency to solidify at ambient temperature, means that conditions for handling and storage cannot be standardised but must be considered and specified for each oil.

FOSFA has published a temperature regime for the handling and storage of a large number of oils, and details of the conditions adopted as suitable are given below. The sensitivity of oils to high temperature makes it essential that when oils are to be heated prior to pumping, it should be achieved with the lowest realistic temperature differential between the heating medium and oil. In consequence, extended heating times prior to discharge are likely to be necessary (where the consistency of the oil is such as to require heating).

Damage

The characteristics of an oil cargo may change while in transit and while this may appear to be damage it is often likely to be no more than a natural change. For example, after some weeks in a tank, sunflower oil may have a deposit of foots (or sediment) on the tank bottom and the oil may appear cloudy on discharge despite having been clear at the time of loading. In such circumstances it is likely that the oil has not been damaged, but a claim may be made when the appearance of the oil has changed between loading and discharge.

Recommended temperature for the carriage of fats & oils

Damage to a fatty oil cargo, leading to it being in an unsatisfactory or even unacceptable condition on discharge, may be caused by:

- Poor temperature control :

The presence of natural antioxidants in a crude fatty oil will not fully protect the oil from improper

carriage and handling. Thus, temperature guidelines for carriage and discharge are recommended to ensure

a satisfactory outturn of cargo.

In particular, exposure of the oil to high temperature can lead to oxidative damage. Some deterioration in quality can be expected during a voyage lasting three to four weeks in conditions where considerable temperature cycling can occur. For this reason, loading of a cargo, the characteristics of which are close to the specified upper limit, will sometimes lead to the oil being outside specification at discharge. - Water ingress : Ingress of water into a tank will cause cargo damage, although the damage is normally more readily reversible than that caused by overheating. A combination of high temperature and excessive moisture content may lead to the formation of free fatty acids, which can have an adverse effect on cargo quality.

- Contamination with chemicals or other substances miscible with the oil :

Chemical contamination is almost always caused by poor cleaning and consequent incomplete removal

of previous cargo residues. However, it should be noted that contamination can have occurred before the oil

is loaded if a road tanker has been inadequately cleaned. Contamination may also be caused by inadequate

processing at the oilseed extraction stage, i.e. if the oil recovered has not been properly cleaned of solvent,

hexane residues may be found in the oil. Chemical analysis can detect minute traces of residues, including

those from the secondlast cargo carried by the ship and modern techniques can detect contaminants as

low as 1 p.p.m. or less.

Contamination, or co-mingling, can also take the form of admixture with another fatty oil. This can occur when a ship carries two different oils, e.g. palm oil and palm kernel oil, and insufficient care is taken to segregate the two cargoes, particularly during loading and/or discharge. This type of contamination does not give rise to any safety risks as far as oil edibility is concerned, but it may make use for the specific purpose originally intended difficult. - Adulteration : Adulteration, the deliberate mixing of two low-valued oils to simulate the composition of a more expensive product, has been largely eliminated by the development of sophisticated techniques for the characterisation of oils. By its nature, adulteration does not involve the ship, as any adulteration will have occurred before loading.

- Admixture : Ships carrying parcels of different oils must be meticulous in preventing cross-contamination due to faulty valves or by a failure to properly clean lines between discharging different parcels. Although different oils are compatible, cross-contamination can seriously affect the end use of a particular product and thus give rise to a substantial claim and possible arbitration.

The crew should remember that carriage of heated edible oil cargoes into cold climates may cause the cargo vapors to solidify inside the cargo tank ventilation piping, effectively preventing the pressure in the cargo tank to equalize. It could potentially result in a catastrophic failure of the cargo tank.

The Food and Agriculture Organization of the United Nations (FAO) recommends the practice for storage and transport of edible fats and oils (CAC/RCP 36-1987). It gives guidance on the maximum temperature required for the various grades during transit and while loading and discharging.

FAO recommended Temperatures during

storage, transport, loading and discharge for Edible Oil's

Notes to table:

- For heated climates, the loading and unloading temperatures for coconut oil & palm kernel oil are minimum 30°C, maximum 39°C or ambient temperature.

- Hydrogenated oils can differ considerably in their slip melting points, which should always be informed. It is recommended that during the voyage, the temperature should be maintained at around the declared melting point and that this should be increased before discharge to give a temperature of between 10°C and 15°C above that point to effect a clean discharge.

- Different grades of palm stearin may have wide variations in their slip melting points and the temperature quoted may need to be adjusted to suit specific circumstances.

- It is recognized that in some cases the ambient temperatures may exceed the recommended maximum figures are shown in the table.

Conclusion

- The aspired temperature of the cargo should be kept throughout the loading/discharging operation and during transit.

- Cargo tanks should imply stripped as soon as the liquid is below the level of the heating coils.

- Clear heating guidance should be given to the master. Any ambiguities should be addressed sooner rather than later.

- The cargo plan should incorporate instructions for stripping heated cargo. Adequate trim and temperature of the shipment should be maintained. Shippers should be mindful that heat loss increases as the level of the cargo drops.

- Heat loss is also quickened if the cargo tank is in contact with the ballast in the adjoining ballast tank. Ballasting should be suspended until the stripping is completed, if it is safe to do so.

- Load temperature should always be increased gradually.

- Overheating of the cargo should be withdrawn.

- Cargo should not be stored at a temperature higher than the ship is devised to carry.

- Cargo temperatures should be checked daily at different levels and the temperature record must be maintained.

- Over-reliance on remote temperature reading equipment should be avoided and temperature should be compared with other means to check accuracy.

We have summarized below some of the special chemical cargoes frequently carried onboard chemical tankers

Handling benzene & methanol safety precautions

Handling carcinogens requirements for certain chemical cargoes

Handling ACRYLONITRILE safety precautions

handling ISOCYANATES safety precautions

handling Sulfuric acid safety precautions

Handling benzene & methanol safety precautions

Requirements of various grade chemical cargo heating

Following detail pages explain all liquid chemical hazards & precautionary measures while carrying at sea.

- Toxicology and associated hazards onboard chemical tankers

- Hazards of vapour given off by a flammable liquid while carrying at sea

- Reactivity of various noxious liquid chemicals

- Most corrosive chemicals carried onboard chemical tankers

- What is putrefaction process of liquid chemicals ?

- Specific gravity,Vapour pressure and boiling point,Electrostatic charging & measuring Viscosity

- General precautions onboard chemical tankers

- Mooring precautions onboard chemical tankers

- Berth precautions onboard chemical tankers

- Cold weather countermeasures, avoiding electric storms

- Restriction on using radio equipments and other mobile devices in cargo working areas

- Handling precautions for carcinogens or cyanide-like substances

- Means of access (gangways or accommodation ladders) safety precautions

- Preparations for hot work and safety precautions

- Precautions against static electricity

Following reference publications provide useful guidance and international regulations for carrying hazardous chemicals at sea.

- SOLAS (latest consolidated edition)

- MARPOL – 73/78 (latest consolidated edition)

- BCH / IBC Code

- International Safety Guide for Oil Tankers and Terminals (ISGOTT)

- Tanker Safety Guide (Chemicals)

- Ship to Ship Transfer Guide (Petroleum)

- Safety in Oil Tankers

- Safety in Chemical Tankers

- IMDG Code

- Supplement to IMDG Code (Including MFAG and Ems)

- SOPEP

- Clean Seas Guide for Oil Tankers

- FOSFA (for Oils, Seeds and Fats)

- Prevention of Oil Spillage through Cargo Pumproom Sea Valves

- CHRIS Guide (USCG)

- Chemical Data Guide for Bulk Shipment by Water (Condensed Chris)

- MSDS for particular cargo carried

- Chemical Tank Cleaning Guide

Main Info pages!

Home page ||| Chemical hazards ||| Cargo planning & Stowage ||| Cargo loading ||| Cargo documents ||| Safe stability ||| Cargo care ||| Preparation for unloading ||| Inert gas systems |||Gas freeing ||| Nitrogen handling ||| Chemical handling Safe practice |||Handling equipments ||| Cargo & Ballast pumps ||| Cargo tanks |||Tank cleaning |||Special cargoes |||Spills emergencies |||Fire protection

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.