Control & operation of centrifugal pumps- starting , stopping, self priming & cavitation- Chemical tanker solution

Why centrifugal pumps ? :

The centrifugal pump has for many years been the most suitable pump onboard chemical tankers where a high

pumping capacity is the most important factor. The size and cost of such a pump does

not increase in proportion with the throughput, as it is not a positive displacement pump. It

requires either the provision of ancillary self-priming equipment for the removal of air in the

system or a separate stripping system.

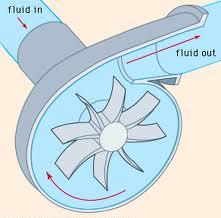

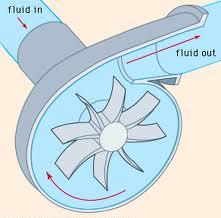

Operation of centrifugal pumps

During operations consideration must be given to the prevailing suction and discharge conditions in relation to the pumps performance characteristics. This is particularly important when operating cargo pumps where the rated capacity is achieved at a relatively high total head. Operation of these pumps with a low total head can grossly exceed the pumps rated capacity and cause excessive liquid velocities in piping systems.

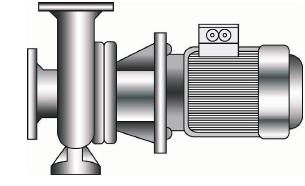

Fig: Centrifugal pump

Discharge Valves

Control of a centrifugal pump can be achieved by either adjusting the pump discharge valve and/or restricting the pump speed. The discharge control valve has three main functions:-

Self Priming

In a self-priming system a discharge control valve performs two duties:-

Centrifugal pumps can be made self-priming if air or gas is removed from the liquid being pumped before it enters the pump suction. The discharge valve on the pump performs as important function during this process by matching the discharge rate of the pump to the natural flow of liquid to the pump suction. The sequence of events is:

Cavitation

A pump is said to cavitate when the pressure at the pump suction has fallen to such an extent that bubbles of vapour are formed in the fluid being pumped.

In a centrifugal pump bubbles can form with great rapidity at the pump suction and may be carried away to regions of higher pressure within the pump. The bubbles then collapse rapidly and in the process of collapsing create a hammer effect. This effect, though minute, if repeated frequently, may cause damage to the pump. The residual effects of cavitation, as well as the cavitation itself, can be a problem and include:-

Starting & stopping of pumps

When dealing with steam hydro electric or electrically driven cargo pumps the following procedures are to be followed:

Emergency stopping of pumps

The emergency stopping of cargo pumps must be carried out by whatever controls are most accessible. All personnel involved in the cargo operations must be aware of the location of cargo pump emergency trips/stops.

Related Info

Pumps operation parameters - risk of cargo pump overload or underload

Risk & hazards of chemical contamination onboard

Cargo hoses handling ,connection and use

PV valves operation and maintenance procedure

Control & operation of centrifugal pumps

How to test a tank environment prior entry ?

How to determine the level of a liquid in a chemical tank

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.

During operations consideration must be given to the prevailing suction and discharge conditions in relation to the pumps performance characteristics. This is particularly important when operating cargo pumps where the rated capacity is achieved at a relatively high total head. Operation of these pumps with a low total head can grossly exceed the pumps rated capacity and cause excessive liquid velocities in piping systems.

Fig: Centrifugal pump

Discharge Valves

Control of a centrifugal pump can be achieved by either adjusting the pump discharge valve and/or restricting the pump speed. The discharge control valve has three main functions:-

- They can be used to regulate pumping rates in variable and constant speed pumps and also to

prevent overloading in constant speed pumps.

- They can be used in conjunction with self priming systems to provide a self priming

capability in centrifugal pumps.

- They can be used to reduce the throughput of a pump, and so reduce the Nett Positive Suction Head required.

Self Priming

In a self-priming system a discharge control valve performs two duties:-

- By restricting the pump throughput, the head is artificially raised to a level above the normal discharge system resistance at that particular throughput.

- Throughput is reduced to a level equal to, or below, the natural flow of liquid to the pump so that cavitation does not occur, i.e. the flow of liquid to the tank suction strum is closely matched to the pump throughput.

Centrifugal pumps can be made self-priming if air or gas is removed from the liquid being pumped before it enters the pump suction. The discharge valve on the pump performs as important function during this process by matching the discharge rate of the pump to the natural flow of liquid to the pump suction. The sequence of events is:

- Discharge commences, pump and separator fill with oil.

- Vacuum pump and valve in gas extraction line are shut-off by float switch in pump separator.

- Discharge valve is fully open, the control system reacting to separator level.

- Tank level falls to point where separator level begins to fall causing the vacuum pump to start to extract the gases filling the top of the separator preventing cavitation. The extracted gases are vented to a slop tank.

- As the separator level falls, the control system partly closes the discharge valve on the pump to reduce the output of the pump.

Cavitation

A pump is said to cavitate when the pressure at the pump suction has fallen to such an extent that bubbles of vapour are formed in the fluid being pumped.

In a centrifugal pump bubbles can form with great rapidity at the pump suction and may be carried away to regions of higher pressure within the pump. The bubbles then collapse rapidly and in the process of collapsing create a hammer effect. This effect, though minute, if repeated frequently, may cause damage to the pump. The residual effects of cavitation, as well as the cavitation itself, can be a problem and include:-

- Erosion of metallic surfaces which, if severe, may create flow disturbances.

- Vibration, which may damage the pump or, more commonly, the instrumentation connected with the pump and installation.

Starting & stopping of pumps

When dealing with steam hydro electric or electrically driven cargo pumps the following procedures are to be followed:

- The Duty Engineer must be given adequate notice of starting or stopping cargo pumps.

- The pumproom is to be checked as soon as possible after any pump unit is started.

- The pump casing is to be vented of air or gas and primed full of liquid before starting the

pump.

- Starting of steam driven centrifugal pumps is to be done in accordance with the

manufacturers instructions, and to be closely monitored by the Duty Engineer.

- Centrifugal pumps are not be run above minimum speed until the Duty Engineer is satisfied

with the operating condition of the drive unit.

- Steam driven centrifugal pumps must be started against a closed discharge valve. Once the

pump is turning the valve should be opened gradually as the pump is brought slowly up to

the desired operating speed.

- Electrically driven centrifugal pumps which run at constant speed, are to be started against

a closed discharge valve. Once the pump is running the discharge valve is to be opened

until the desired discharge pressure is achieved.

- The stopping of steam driven centrifugal pumps must be carried out by the Duty Engineer,

however, routine stopping may be carried out using remote controls providing prior notice

has been given to the Duty Engineer.

- The stopping of electrically driven pumps may be carried out from the Cargo Control Room. Before stopping the pump the load on the pump is to be reduced by closing in on the discharge valve. The Duty Engineer must always be advised of when such a pump is being stopped to allow him to monitor the generating plant as the electrical load changes.

Emergency stopping of pumps

The emergency stopping of cargo pumps must be carried out by whatever controls are most accessible. All personnel involved in the cargo operations must be aware of the location of cargo pump emergency trips/stops.

Related Info

Pumps operation parameters - risk of cargo pump overload or underload

Risk & hazards of chemical contamination onboard

Cargo hoses handling ,connection and use

PV valves operation and maintenance procedure

Control & operation of centrifugal pumps

How to test a tank environment prior entry ?

How to determine the level of a liquid in a chemical tank

- Cargo line leakage countermeasures

There are many reason that may lead to cargo line failure on board chemical tanker. Galvanic corrosion in the cargo and stripping pipelines may cause several leakage. One of the sources of such corrosion in pipelines is variation in corrosion resistance at adjacent points in the piping. -

Checklist for handling dangerous liquid chemicals in bulk

Is information available giving the necessary data for the safe handling of the cargo and, where applicable, is a manufacturer's inhibition certificate available? Information on the product to be handled should be available on board the ship and ashore before and during the operation. -

Recommended temperature monitoring equipments onboard

Temperature sensors are fitted so that the temperature of the cargo can be monitored, especially where required by the IBC Code. It is important to know the cargo temperature in order to be able to calculate the weight of cargo on board, and because tanks or their coatings often have a maximum temperature limit. Many cargoes are temperature sensitive, and can be damaged by overheating or if permitted to solidify. Sensors may also be fitted to monitor the temperatures of the structure around the cargo system. -

Practical example of solving tank cleaning problems

Tank cleaning is essential on-a chemical tanker, but it must be recognised as a potentially hazardous operation, and rigorous precautions should be observed throughout the process. Together with gas freeing, it is probably the most hazardous operation routinely undertaken on a chemical tanker.

Pre-cleaning /washing of cargo tanks - Pre-cleaning /washing of cargo tanks

Washing between different grades of cargo is the most common reason for tank cleaning. In most cargo sequences on chemical tankers, this cleaning may consist of no more than a simple hot or cold seawater wash. A simple water wash will disperse many types of chemicals and has been found effective between clean petroleum products such as gas oil and kerosene. - Final cleaning of cargo tanks prior loading

Method of final cleaning to be used depends on both previous cargo and cargo to be loaded. As a general rule the tanks and piping shall be completely drained of water or residues before loading. The bottom of the tanks may have to be dried up with rags. - Tank cleaning and posoning hazards

Certain substances affect the tissues locally as an irritant (cashew nut shell oil) or cause grave damage to the eyes, skin or mucous membranes (e g strong acids and caustic). Other substances may be absorbed by contact to the skin without local effects (e g nitrobenzene, aniline). - Testing of tanks and cargoes

Most common tests and checks for oil and chemical cargoes include testing tank walls for cleanliness. Testing is normally carried out by independent surveyors who, according to local practice or a written agreement in the charter party, are accepted by shipper, receiver and owner. -

Practical tank cleaning methods for various noxious liquid cargo

Tanks that may have contained monomer or drying oils should first be cleaned with sufficient cold water quantities to avoid polymerization of cargo residues. In some cases, it is necessary to employ tank cleaning chemicals, but their use is generally limited as it may be difficult to dispose of slops. -

Special tank cleaning method

If a special method involving cleaning agents is to be used, it may create an additional hazard for the crew. Shipboard procedures should ensure that personnel are familiar with, and protected from, the health hazards associated with such a method. The cleaning agents may be added to the wash water or used alone. The cleaning procedures adopted should not entail the need for personnel to enter the tank. -

Determining proper tank cleaning by acid wash method

The acid wash method is used if there is any suspicion that a cargo of aromatics may have been contaminated by a previous oil cargo. The method is also used as a check that a tank is sufficiently cleaned before loading aromatics. -

Supervision of all tank cleaning and gas freeing operations

Tank cleaning is essential on-a chemical tanker, but it must be recognised as a potentially hazardous operation, and rigorous precautions should be observed throughout the process. Together with gas freeing, it is probably the most hazardous operation routinely undertaken on a chemical tanker. -

Disposal of tank washings, slops and dirty ballast - safe method

During normal operations of a chemical carrier, the main need to dispose of chemical residues, slops or water contaminated with cargo will arise during or immediately after tank cleaning. Final disposal of slops or washwater should be in accordance with the ship's P&A Manual. Tank washings and slops may be retained on board in a slop tank, or discharged ashore or into barges. -

PV valves -function and maintenance requirements

Pressure/Vacuum valves are designed to provide protection of all cargo tanks against over/under pressure and provide for the flow of small volumes of tank atmosphere resulting from temperature variations in the cargo tank(s) and should operate in advance of the pressure/vacuum breaker, where IG system is in use.... - Deck seal, tank non return valves and tank gauging requirements

On vessels fitted with an inert gas system it is a requirement to maintain a positive seal between the cargo tanks and the inert gas generation plant this is usually accomplished by the use of a non - return valve and a Deck Water Seal... -

Loading / stress computer

This instrument is provided to supplement the stability booklet for the vessel. It allows the Officer responsible, to carry out the various complex calculations required to ensure that the ship is not overstressed or damaged during the carriage of the nominated cargoes.. -

Various cargo handling safety equipments carriage requirements

It is essential on chemical tankers that everyone knows his ship's safety equipments thoroughly prior handling noxious chemical cargo. Also the master/chief officer must assume responsibility for this. -

Vapour emission control requirement for chemical tankers

Vessels fitted with a VEC system must have an independent overfill alarm providing audible and visual warning. These are to be tested at the tank to ensure their proper operation prior to commencing loading, unless the system is provided with an electronic self-testing capability. Fixed gauging systems must be maintained in a fully operational condition at all times. ..... -

Draegar Chemical detector tubes use and reading correction guideline

These instruments, often referred to as Draeger tubes, normally function by drawing a sample of the atmosphere to be tested through a proprietary chemical reagent in a glass tube. The detecting reagent becomes progressively discoloured if a contaminant vapour is present in the sample. The length of the discoloration stain gives a measure of the concentration of the chemical vapour which can be read from the graduated scale printed on the tube. Detector tubes give an accurate indication of chemical vapour concentration, whatever the oxygen content of the mixture -

Requirements of various grade chemical cargo heating

: The voyage orders will contain heating information, if heating is required. As a rule the final heating instructions are given by the Shipper in writing to the Master / Chief Officer in the port of loading. If those written instructions are not given, the master should request them and issue a Letter of Protest if they are not received at departure. In the latter case the management office should be immediately informed. -

Recommended temperature monitoring equipments onboard

:Temperature sensors are fitted so that the temperature of the cargo can be monitored, especially where required by the IBC Code. It is important to know the cargo temperature in order to be able to calculate the weight of cargo on board, and because tanks or their coatings often have a maximum temperature limit. Many cargoes are temperature sensitive, and can be damaged by overheating or if permitted to solidify. Sensors may also be fitted to monitor the temperatures of the structure around the cargo system. -

Cargo instruments

:In order to maintain a proper control of the tank atmosphere and to check the effectiveness of gas freeing, especially prior to tank entry, several different gas measuring instruments need to be available for use. Which one to use will depend upon the type of atmosphere being measured. -

Liquid level gauges

:The accuracy required of chemical carrier level gauges is high because of the nature and value of the cargo. To limit personnel exposure to chemicals or their vapours while cargo is being handled, or during carriage at sea, the IBC Code specifies three methods of gauging the level of a liquid in a tank - open, restricted or closed -

Overflow control

:Certain cargoes require the designated tank to be fitted with a separate high level alarm to give warning before the tank becomes full. The alarm may be activated by either a float operating a switch device, a capacitive pressure transmitter, or an ultrasonic or radioactive source. The activation point is usually pre-set at 95% of tank capacity. -

Oxygen analysers

:Oxygen analysers are normally used to determine the oxygen level in the atmosphere of an enclosed space: for instance, to check that a cargo tank can be considered fully inerted, or whether a compartment is safe for entry.

Vapour detection

:Ships carrying toxic or flammable products (or both) should be equipped with at least two instruments that are designed and calibrated for testing the gases of the products carried. If the instruments are not capable of testing for both toxic concentrations and flammable concentrations, then separate sets of instruments should be provided. -

Alarm circuit

:An important feature of many modern measurement and control instruments is the ability to signal a particular situation. This can be a main operational alarm that gives an indication of a pre-set situation such as liquid level in a tank, or a malfunction alarm indicating a failure within a sensor's own operating mechanism. The designs and purposes of alarm and shutdown circuits vary widely, and their operating system may be pneumatic, hydraulic, electrical or electronic. Safe operation of plant and systems depends on the correct operation of these circuits and a knowledgeable reaction to them. - Venting of cargo tanks safety procedure

The cargo tank venting system should be set for the type of operation to be performed. Cargo vapour displaced from tanks during loading or ballasting should be vented through the installed venting system to atmosphere, except when return of the vapour to shore is required. The cargo or ballast loading rate should not exceed a rate of vapour flow within the capacity of the installed system. .....

Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing. If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Contact us

Copyright © 2011 Chemical Tanker Guide.com All rights reserved.